How to use metal dome? Metal snap domeMetal snap domes are used as tactile switch elements in keypads and control panels. They sit between the PCB circuit and the overlay. When pressed, the dome collapses to complete the circuit and provides a crisp “click” feedback.

They can be applied individually or as a pre-arranged metal dome array with adhesive backing, making assembly fast and precise. Choosing the right dome size, force, and shape depends on the desired tactile feel and application requirements.

What Is the Metal Dome Used For?

A metal dome is a small, circular or cross-shaped component made from thin stainless steel. It sits between a circuit board and a top layer, typically within a membrane switch, keypad, or control panel. Its main purpose is to provide tactile feedback and electrical connectivity when pressed.

When you press the button, the dome snaps downward, touching the circuit beneath it and closing the electrical path. Once you release it, the dome pops back into shape. That’s the tactile “click” feeling you notice every time you press a button on a remote, calculator, or industrial control device.

Because of their responsiveness and long lifespan, metal domes are used in industries that require reliability and accuracy. You’ll find them in medical devices, consumer electronics, automotive dashboards, military equipment, and industrial controls.

What makes them even more appealing is their durability. A well-designed metal dome can withstand over one million cycles without losing its shape or conductivity. That means less downtime, fewer replacements, and consistent performance for years.

How Does a Metal Dome Work?

A metal snap dome acts as both a mechanical spring and an electrical conductor. It’s positioned between two layers — the upper layer (graphic overlay or adhesive spacer) and the lower layer (circuit board or contact pad).

When pressure is applied to the dome’s surface, the metal flexes downward due to its spring structure. At the moment it collapses, it touches the contact pad on the PCB. This closes the circuit and sends a signal to the device — for example, turning on a light, adjusting a setting, or triggering a command.

Once the pressure is released, the dome springs back to its original convex shape. This “snap” action produces the tactile click that tells the user the button was successfully pressed.

This process happens in milliseconds, providing both tactile and auditory feedback. The user doesn’t have to look at the interface — they can feel the confirmation instantly. That’s why metal domes are so widely used in devices that require precision and responsiveness.

How Do Metal Domes Enhance Tactile Feedback?

The tactile feel of a button can shape the entire user experience. A soft or unclear response can make a product feel cheap, while a clean, defined click adds a sense of quality and control.

Metal domes are designed specifically to enhance this feedback. Their spring-like structure creates a perfect balance between resistance and responsiveness. When pressed, they offer just enough force to signal engagement, followed by a distinct click when the circuit closes.

This tactile sensation reassures the user that the button has been pressed successfully. In professional applications, such as medical devices or control systems, this feedback isn’t just for comfort — it’s a critical design element that prevents errors.

Different metal dome types produce different tactile forces and click ratios. In addition, their repeatable performance ensures that every button press feels identical, even after thousands of uses.

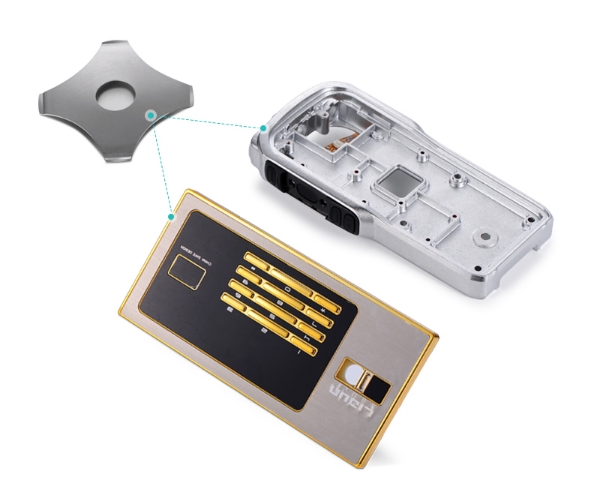

What Are the Different Metal Dome Shapes?

Metal domes come in various shapes, and each one serves a distinct purpose. The most common metal dome shapes include:

- Four-Leg (Cross) Dome: The most widely used design. It offers a strong tactile feel and is easy to position.

- Triangle Dome: Compact and lightweight, this type is ideal for smaller keypads where space is limited.

- Round Dome: Known for its smooth feel and uniform response, the round dome is often used in devices requiring consistent feedback.

- Oblong (Rectangular) Dome: Best for long or narrow buttons. It provides stable contact over a wider area and is often used in rocker switches or elongated keys.

- Custom Dome: Some applications require unique shapes or custom tactile forces. BEST Technology can design custom domes to suit specific operating environments.

Each metal dome type has unique mechanical characteristics. The force, travel distance, and tactile feedback depend on its diameter, thickness, and curvature.

Which Metal Dome Shape Is Best for Your Application?

Choosing the best metal dome shape depends on how the button will be used and the feel you want to deliver.

- Consumer electronics: Devices like remote controls, keyboards, and calculators often use four-leg domes.

- Medical equipment: Here, round domes are preferred because of their consistent response and gentle click, minimizing user fatigue during repeated use.

- Automotive panels: Oblong domes perform well in dashboards or steering wheel controls because they offer stability even under vibration.

- Industrial machines: In rugged environments, triangle domes are favored for their sharp and responsive feel, giving operators a confident sense of engagement.

It’s also important to consider the actuation force — the pressure required to collapse the dome. A higher actuation force gives a firmer feel, while a lower one offers a softer touch.

So, before choosing a dome type, think about your user’s preferences, product environment, and design goals. The best shape is the one that balances comfort, performance, and durability.

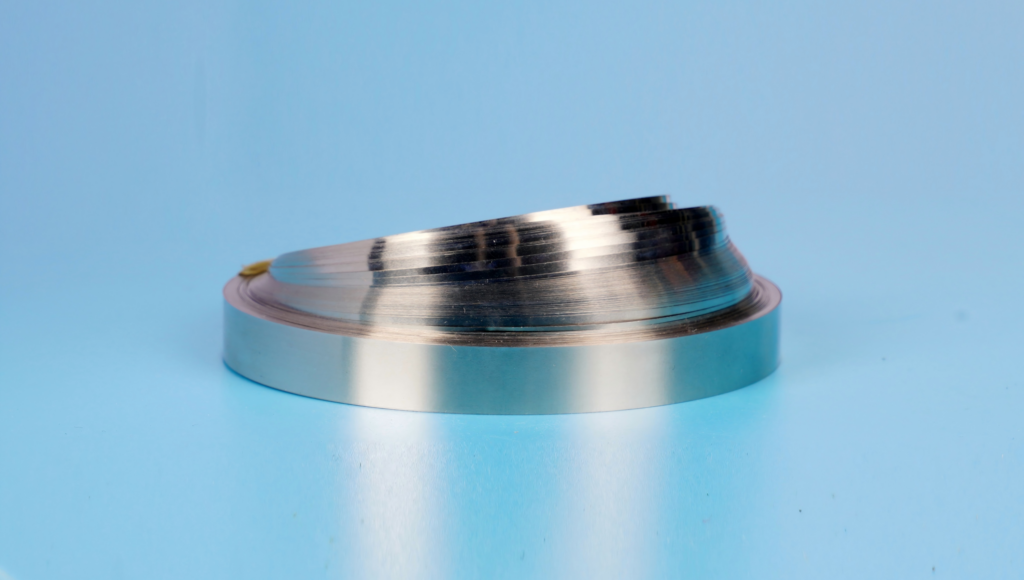

What Material Is the Best Metal Dome?

Most metal domes are made from stainless steel, typically SUS301 or SUS304. This material is highly valued for its elasticity, conductivity, and corrosion resistance. It can flex millions of times without deformation, which is essential for products that require long-term performance.

In environments where moisture or chemical exposure is a concern, a nickel-plated stainless steel dome provides additional protection. The nickel layer enhances conductivity and prevents oxidation, extending the dome’s lifespan.

For special applications, such as medical instruments or aerospace equipment, domes may be coated with gold plating. Gold enhances conductivity even further and provides exceptional resistance to corrosion.

When selecting material, consider both performance and cost. Stainless steel offers the perfect balance — strong, flexible, and affordable. For most designs, it’s the go-to material for metal snap domes.

How to Use Metal Snap Domes?

A metal snap dome is usually mounted on a circuit board or a flexible membrane layer. It’s positioned directly above a contact pad. A thin adhesive spacer keeps it in place and separates it from other layers.

Here’s how you can use it effectively:

- Placement: Align the dome accurately over the contact area. Misalignment can affect tactile response or electrical performance.

- Adhesion: Use high-quality adhesive tape or a PET carrier sheet to hold the dome firmly in place.

- Overlay: Apply a graphic overlay or top layer to protect the dome and provide visual identification for the button.

- Testing: After assembly, perform tactile and continuity tests to confirm proper operation.

When used correctly, metal domes offer fast response, consistent performance, and extended lifespan. They’re easy to integrate into various devices, and because they’re mechanical components, they don’t require soldering or complex assembly steps.

How to Make a Metal Dome?

Creating a metal dome involves precision and engineering. It’s not a simple stamping process. The process usually includes these key steps:

- Material Selection: High-grade stainless steel sheets are chosen based on required elasticity and conductivity.

- Stamping: Using precision dies, the metal is stamped into the desired dome shape. This process defines the dome’s curvature and click force.

- Deburring and Cleaning: The edges are polished to remove any sharp burrs and to ensure a smooth surface.

- Heat Treatment: The dome is heat-treated to stabilize its spring characteristics and improve fatigue resistance.

- Plating (Optional): Depending on requirements, domes can be nickel or gold plated to enhance corrosion resistance and conductivity.

- Inspection: Each dome undergoes tactile force and dimensional testing to guarantee consistency before packaging.

The final result is a tiny yet powerful component that can transform how a button feels and performs.

Manufacturing metal domes requires advanced precision equipment and strict quality control. Even minor variations in thickness or curvature can affect tactile performance.

Conclusion:

Metal domes determine the tactile feel of each keypress, enhance product quality, and provide reliable electrical performance in countless applications.

At Best Technology, we specialize in high-quality metal snap domes, tailored for precision and durability. Our engineering team ensures each dome meets strict performance standards to fit your application perfectly.

If you’re ready to explore custom metal domes for your next project, reach out to us at ? sales@metal-domes.com