SUS304 stainless steel is an austenitic stainless steel containing 18–20% chromium and 8–10.5% nickel, with excellent corrosion resistance and ductility.

Metal domes made of it can maintain elasticity and stable conductivity for a long time in harsh environments such as humidity and salt spray. It is the preferred material for keyboards, car central control, etc. that require high-reliability touch.

What are the benefits of SUS304?

SUS304 stands out in the stainless steel family for its exceptional balance of corrosion resistance, strength, and formability. It contains approximately 18% chromium and 8% nickel, which makes it a non-magnetic austenitic stainless steel.

In the field of metal domes, this property becomes even more valuable. Metal dome switches must remain consistent through millions of actuations. SUS304 ensures they maintain tactile feedback and don’t deteriorate with time. This material also offers excellent mechanical strength while still being easy to work with, which lowers manufacturing costs without compromising quality.

The biggest benefits?

- Corrosion Resistance: Whether it’s in contact with air, moisture, or even mild acids, SUS304 resists rust and staining far better than other metals.

- Strength with Flexibility: This combination makes it perfect for metal dome switches, where the material must flex thousands or even millions of times without breaking.

- Temperature Stability: It performs well in both high and low temperatures without losing integrity.

- Ease of Fabrication: Whether it’s stamped, drawn, or rolled, SUS304 shapes beautifully.

This material is a blend of function and form—exactly what industries like electronics, automotive, and medical demand.

How long will 304 stainless steel last?

The longevity of 304 stainless steel—which is equivalent to SUS304—is remarkable. In most conditions, it can last over 50 years without corrosion or fatigue.

Even in more challenging environments, like those exposed to moisture or light chemicals, it can last decades with minimal maintenance. That’s why it’s widely used in metal dome arrays, where long-term reliability is essential.

In dome switch applications, this longevity translates into extended product lifecycles and reduced failure rates. When properly handled and protected from highly corrosive environments, SUS304 can outlast most other metals commonly used in electronics and mechanical components.

Which is better SUS304 or SS304?

Here’s the twist: SUS304 and SS304 are essentially the same thing.

- SUS304: This is the Japanese standard (JIS) for stainless steel.

- SS304: This is the American standard (AISI) for the same composition.

While the standards differ slightly in specification, the material properties are almost identical. Both refer to a stainless steel that contains about 18% chromium and 8% nickel.

The decision to label the material as SUS304 or SS304 usually depends on regional or market preferences. For example, Japanese manufacturers often use SUS304, especially in high-precision parts like metal domes.

Is SUS304 stainless steel good quality?

Yes, SUS304 stainless steel meets international standards for safety, strength and chemical composition. In tactile applications such as metal domes, the high purity of SUS304 means more predictable and consistent tactile responses.

- It meets international standards (JIS, ASTM, ISO).

- It offers a consistent chemical makeup and predictable performance.

- It undergoes rigorous testing during production.

- It’s widely certified for food-grade safety, medical use, and electronics.

The high quality of SUS304 ensures performance doesn’t degrade over time. With proper usage, this material keeps working without losing its functionality, even under repetitive physical pressure.

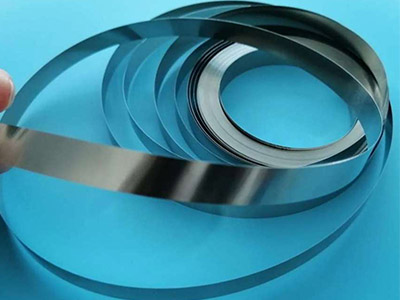

Sus304 stainless steel properties

SUS304 stainless steel has a composition that gives it ideal characteristics for demanding environments. Its physical and mechanical properties include:

| Property | Value |

|---|---|

| Material Type | Austenitic stainless steel |

| Chemical Composition | ~18% Chromium, ~8% Nickel |

| Density | 7.93 g/cm³ |

| Melting Point | 1400–1450°C |

| Tensile Strength | >= 505 MPa |

| Yield Strength | >= 215 MPa |

| Elongation (in 50mm) | >= 40% |

| Brinell Hardness | ~201 HBW |

| Magnetic Properties | Non-magnetic (annealed condition) |

| Corrosion Resistance | Excellent in most environments |

| Thermal Conductivity | ~16.2 W/m·K |

| Electrical Resistivity | ~0.73 µ?·m |

| Formability | Excellent |

| Fatigue Resistance | High (ideal for repeated pressing) |

These properties make SUS304 strong, ductile, and formable. The smooth finish of the material also improves conductivity in electrical applications, a key advantage for tactile domes and switches.

Its thermal resistance makes it stable at both high and low temperatures. In dome switches, this means stability in various working conditions, whether indoors, outdoors, or in industrial environments.

Sus304 vs 304 stainless steel

There’s often confusion between SUS304 and 304 stainless steel, but they are technically the same. The only difference lies in the naming system. SUS304 is the designation used in Japan, while 304 is the term used under the AISI and ASTM standards globally. Both refer to the same material composition: austenitic stainless steel with 18% chromium and 8% nickel.

From a performance perspective, there is no meaningful difference. Both offer the same level of corrosion resistance, strength, ductility, and longevity. If you’re sourcing materials or components, whether it’s labeled SUS304 or 304, you can expect the same results.

For dome switch production, manufacturers often use the SUS304 label, especially in Asian markets. But when exporting or communicating internationally, it’s common to refer to it as 304 stainless steel.

Is 304 stainless steel better than 316?

304 stainless steel (SUS304) is more than enough for most uses. But 316 stainless steel adds molybdenum, which gives extra protection against chlorides and harsh chemicals.

So if you’re in a marine, chemical, or salty environment, 316 is stronger against corrosion.

But for everyday applications, metal domes, electronics, and indoor use, 304 is ideal. It’s lighter on the budget, easier to fabricate, and widely available.

Unless your product needs to survive in seawater or bleach, SUS304 is more cost-effective and reliable.

Where is SUS304 stainless steel commonly used?

You’ll find SUS304 almost everywhere:

- Metal dome switches and tactile components

- Kitchen equipment (sinks, pots, utensils)

- Medical tools and implants

- Architectural panels and fasteners

- Electronics and smartphone components

- Automotive parts exposed to weather and moisture

Its resistance to rust and great appearance make it ideal for both visible and hidden applications.

In the world of metal domes, SUS304 is popular because it provides perfect tactile response while withstanding repetitive pressure.

Conclusion:

SUS304 stainless steel is rust-proof, crush-resistant, and suitable for almost any shape and function. Whether you are manufacturing high-end kitchenware or precision spring switches, this material will prove its value.

Looking for high-quality dome switches made from SUS304 stainless steel? Reach out to us anytime at sales@metal-domes.com