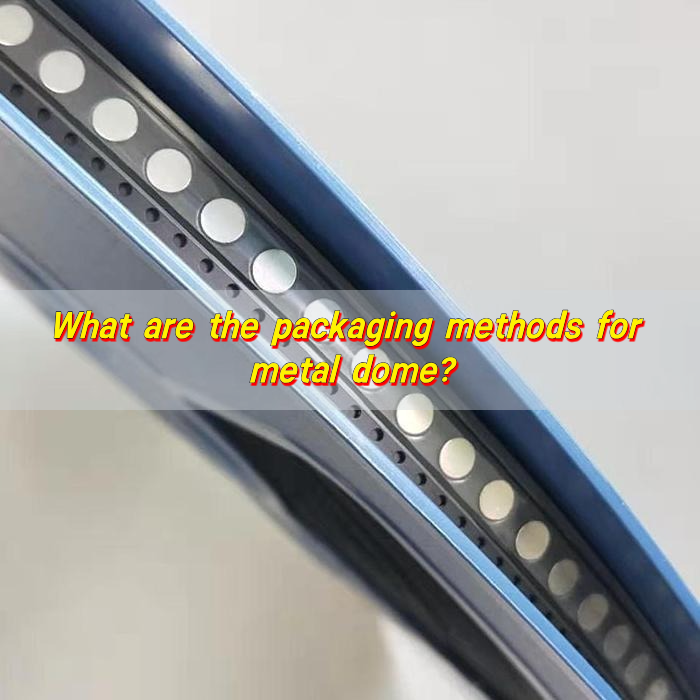

There are many ways to package Metal dome. Most of metal dome are packed in bulk, in a PE bag, or bottle, so it is still named metal dome, and packing will be named “In Bulk“; if in tube then named as “Tube Metal Dome“; if in tape & reel for auto SMT machine, then “Tape & Reel Dome”.

What is metal dome packaging?

Metal dome packaging refers to how metal domes—those small yet essential parts of tactile switches—are stored, protected, and delivered. Because these components are so delicate and precise, packaging must ensure cleanliness, prevent deformation, and allow for easy assembly. The right dome packaging not only maintains product integrity but also speeds up manufacturing workflows.

It’s not just about wrapping; it’s about reliability. If you receive bent or scratched domes, your switch performance could fail. That’s why manufacturers use smart, tested packaging methods designed specifically for different purposes—mass production, prototyping, or machine placement.

How are metal domes packed?

There’s no one-size-fits-all approach to metal dome packaging. The method depends on how the domes will be used. Are they going straight into a machine? Are they being tested manually by engineers? Or are they stored for future projects? Depending on the answer, domes are packed using one of three main methods. Each one has a clear purpose.

Bulk packaging

Tube packaging

Tape & Reel packaging

What is Tape & Reel packaging?

Tape & Reel dome packaging is the top choice for automated assembly. These domes are mounted on a carrier tape that’s wound on a reel. Each dome fits perfectly in a designated cavity on the tape, secured with a cover layer to prevent movement or damage.

This method is specifically designed for high-speed pick-and-place machines. If you’re running an SMT (Surface Mount Technology) line, Tape & Reel is the most efficient option. It eliminates manual handling, reduces contamination, and improves precision during installation.

It’s especially useful in mass production of membrane switches or PCBs where consistency is key. You also reduce waste and errors, which boosts yield rates. For those seeking streamlined automation, Tape & Reel domes are a no-brainer.

What are the most common metal dome packaging methods?

While Tape & Reel is high-tech and fast, it’s not the only method out there. In fact, many clients still choose Bulk or Tube packaging depending on their requirements.

- 1. Bulk Packaging (PE Bags or Bottles)

This is the simplest and most cost-effective packaging style. Domes are placed loosely in PE ziplock bags or plastic bottles. They’re sorted by size and type, making it easy for engineers or assembly workers to access them by hand.

It’s called “In Bulk” because the domes aren’t separated or organized in individual slots. For manual assembly or prototyping, this method works well. However, it’s not recommended for highly sensitive or automated operations since there’s a greater chance of deformation or contamination.

Despite that, it remains the most popular method due to its affordability and simplicity. Ideal for small-batch orders, DIY projects, or flexible assembly setups.

Also referred to as “Tube Metal Dome”, this method involves placing domes in long, narrow plastic tubes. Each dome is stacked inside, protected from dust and pressure.

This approach offers better protection than bulk and is still manageable for manual handling. The uniform alignment of domes in the tube also allows semi-automatic insertion or controlled pick-up in cleaner environments.

Tube packaging strikes a balance between cost and protection, making it a good fit for mid-volume production or field installations.

As covered earlier, this is the gold standard for automation. Every dome is placed precisely in position, ready for robotic hands. It’s clean, controlled, and reliable. Though it’s the most expensive method, its efficiency in large-scale production often offsets the higher cost.

Which packaging suits bulk metal domes?

For bulk orders where domes are not immediately going into high-speed machines, Bulk Packaging is the right choice. Whether shipped in PE bags or bottles, this method ensures that thousands of domes can be delivered at once with minimal cost and preparation.

Since domes are small, lightweight, and easy to count or weigh, bulk packaging allows quick access. However, buyers should make sure that the packaging is anti-static and cleanroom-friendly to avoid any surprises down the line.

How to choose the right packaging for metal domes?

The best way to choose your dome packaging is to ask yourself three key questions:

- How will the domes be installed? If you’re using machines, go with Tape & Reel. If manually, then bulk or tube works fine.

- What’s your volume? For large quantities, bulk saves money. For precise placement, Tape & Reel saves time.

- What’s your budget? Bulk is the most affordable, followed by tubes. Tape & Reel costs more but is worth it for automated lines.

Also, consider your storage environment. If domes will sit in stock for a long time, opt for airtight bottles or tubes to reduce contamination risk. Clean packaging also matters for industries like medical devices or aerospace, where performance can’t be compromised.

Why does packaging matter so much?

Metal dome packaging directly affects the performance and reliability of the final product. Poor packaging can bend domes, introduce static, or contaminate contacts. That leads to faulty circuits, failed assemblies, or reduced lifespan of the device.

Well-packed domes reduce handling errors and ensure consistent tactile response. Especially for domes used in control panels, car electronics, or medical instruments, accuracy and cleanliness matter.

Conclusion:

When choosing metal dome packaging. The way domes are packed speaks volumes about their readiness, reliability, and long-term performance. From cost-effective Bulk packaging, reliable Tube domes, to precision-engineered Tape & Reel domes, every method serves a clear purpose.

For clean, accurate, and high-performance dome packaging, work with BEST Technology Metal Dome Manufacturers. We not only sell metal domes, we deliver them ready to use.

Need help choosing the right dome packaging? Contact us today at sales@metal-domes.com