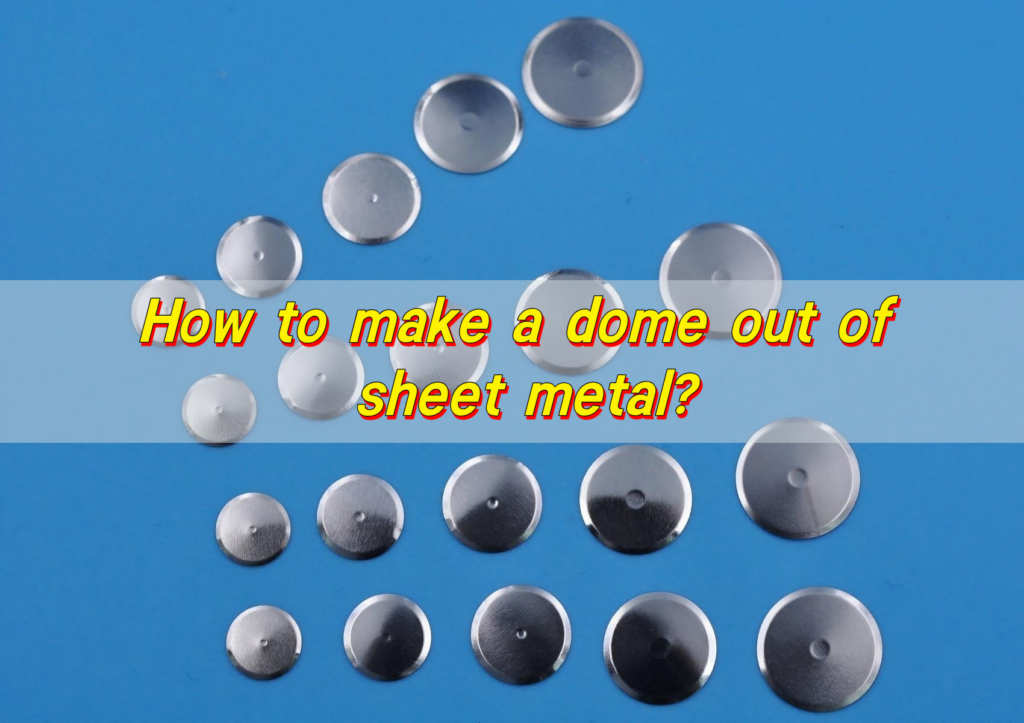

How to make a dome out of sheet metal? To make a metal dome, you must first select a suitable metal plate, such as stainless steel or copper alloy, to ensure that it has excellent elasticity and conductivity. Then, according to the design drawings, use laser cutting or stamping equipment to accurately cut it into the required shape. Then, stamping is used to form the metal plate into the shape of the dome to ensure dimensional accuracy. In order to prevent corrosion and improve conductivity, surface treatment such as gold plating or silver plating is required.

How to make a dome out of metal?

Making a dome out of metal begins with choosing the right kind of sheet metal. Then, it involves shaping that metal into a smooth, curved form.

The most common process is called hydroforming, which uses fluid pressure to mold the sheet metal into a dome. Another popular technique is metal spinning. This method rotates a flat sheet on a lathe while a tool presses it into the desired shape.

Manual forming can also work for simple domes. Using a hammer and a sandbag or a wooden form. It takes time and patience, but it’s possible with the right technique.

What material are the sheet metal used to make dome made of?

The material matters—a lot. Most sheet metal domes are made from stainless steel, brass, aluminum, or copper. These metals are durable, corrosion-resistant, and easy to form. Stainless steel is often chosen for switches and tactile applications because it snaps back well and doesn’t corrode easily.

Aluminum is lightweight and soft, making it great for artistic or structural domes where minimal weight is crucial. Copper and brass, though more expensive, are preferred for their visual appeal and malleability.

Choosing the right material depends on what your dome will be used for. If it’s for electronics or membrane switches, metal domes made of stainless steel are ideal.

What’s the best method to make a metal dome?

It depends on the final purpose. For tactile domes in electronics, stamping and coining offer the best precision. These methods involve pressing the metal with a die to create a uniform shape. They’re fast, reliable, and excellent for mass production.

For larger or artistic domes, spinning is often the best choice. It’s smooth, accurate, and retains the integrity of the metal. When intricate designs or one-off pieces are needed, hydroforming or press forming might be used.

Each technique has its own benefits. What matters is the consistency of the shape, the strength of the metal, and the surface finish.

How do you avoid dents when making domes?

This is one of the biggest challenges. Even the smallest dent can ruin the symmetry of a dome. To avoid dents, you must work slowly and with control. Never rush the forming process. Use proper support underneath the metal.

If you’re using tools, make sure they’re smooth and clean. Sharp edges or dirty surfaces can scratch or dent the metal. Wearing gloves also helps to keep oils off the sheet, which might affect the finish or create slippery areas.

How thin should sheet metal be for domes?

Thickness depends on the dome’s purpose. For small tactile metal domes used in electronics, the thickness is usually between 0.05 mm to 0.15 mm. This thin profile allows the dome to snap quickly while still offering resistance.

Thinner metal is easier to form but may not hold shape as well under stress. Thicker metal is stronger but harder to shape.

Find the right balance. For most metal domes, especially snap domes, the perfect thickness allows for both form and function—providing tactile feedback without breaking.

What tools make dome metal shaping easier?

The right tools make all the difference. For small domes:

- Stamping dies: Ideal for precise shaping in mass production

- Coining machines: Apply pressure for uniform curves

- Vacuum forming setups: Help form the metal without stretching it too thin

Each tool has a purpose. Combining manual and machine methods can often give the best results.

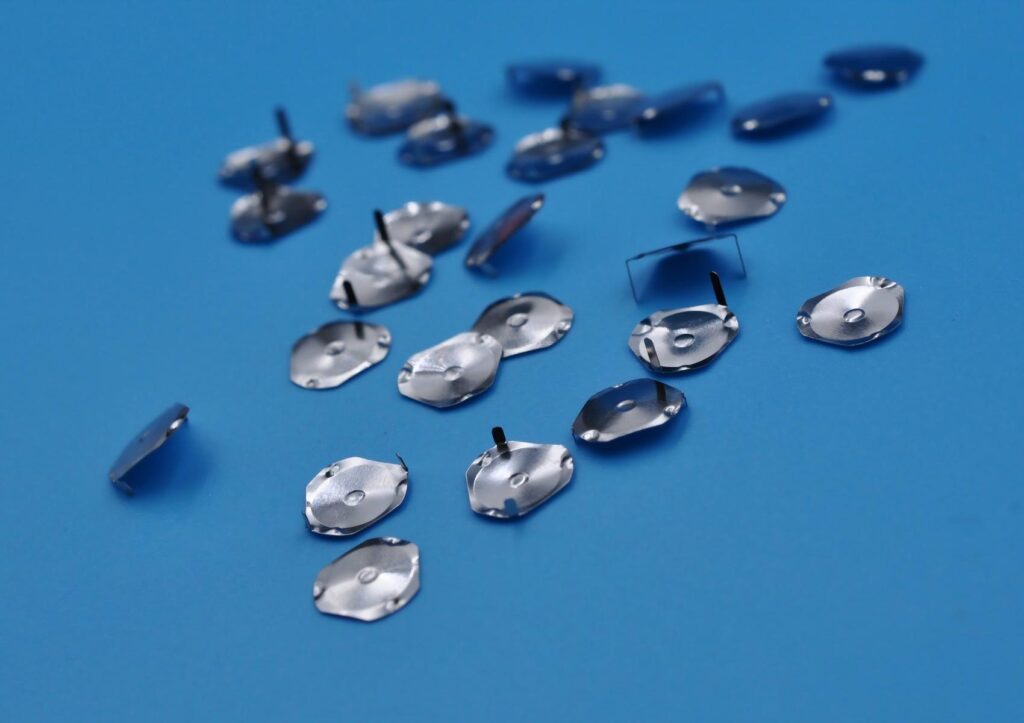

How are metal dome of different shapes made?

The production of metal dome of different shapes (such as round, cross, triangle, and ellipse) mainly revolves around the engraving, lamination and assembly process of PET plastic materials. The process emphasizes precision control and drawing customization to adapt to various shapes.

According to the design drawings (customized for different shapes), the PET plastic material is track engraved or stamped. For example, round or cross-shaped metal dome requires a specific mold to ensure the shape is accurate; this step can be processed in batches, but the more complex the shape, the more it relies on high-precision equipment and customized drawings.

Key points for customization of different shapes:

- Circular and elliptical: The easiest to make, low cost, and long life, mainly relying on standard stamping dies; the elliptical needs to pay attention to arc symmetry.

- Cross and triangle: The shape is complex, and customized drawings and fixtures are required. It is easier to deviate when laminating, and precision control must be strengthened.

- Customization of special shapes: Drawings can be designed according to needs (such as customized strength 100-5000 grams), but additional mold costs are required, and the difficulty of production increases with the complexity of the shape.

The entire process emphasizes environmental cleanliness, tool precision and material adaptation to ensure the conductivity and durability of various metal dome.

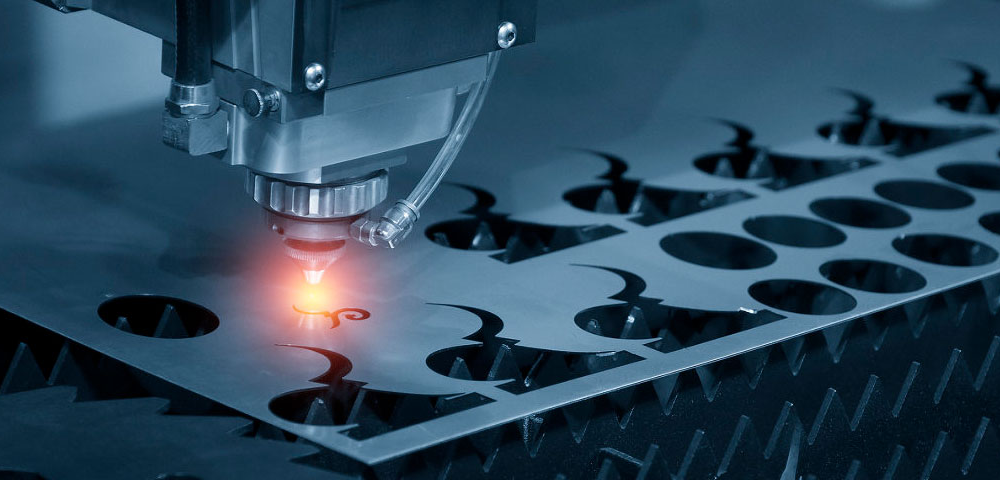

Is laser cutting better for dome metal?

Laser cutting allows precise, clean cuts without physically touching the metal. This means there’s less risk of scratches or deformities. It’s especially useful for cutting out the blank shapes before forming begins.

For small dome switches, laser cutting is ideal. It ensures each dome starts with exactly the same size and shape, which means better consistency and performance later. In contrast, mechanical cutting might leave burrs or rough edges.

Laser cutting also reduces waste. It’s computer-controlled, so every sheet of metal is used efficiently. That makes it not just better for quality but also better for cost.

Conclusion:

Making a dome out of sheet metal is a critical process, from choosing the right metal to carefully shaping it. The entire process can be done by stamping, spinning or hydroforming – each process has its own unique advantages.

Selecting the right thickness and tools ensures smooth results. Avoiding dents takes patience and smart techniques. Whether you’re making a tactile dome switch or a structural dome, precision is everything.

If you’re ready to start your own metal dome project or need help creating one, our experts are here to help. Reach out to us at sales@metal-domes.com