Metal dome production is a special process that uses stamping dies to cold stamp metal materials into precision parts. Its production process includes material collection, testing, die setting, stamping, cleaning, testing, packaging and other steps to ensure that the product meets high quality standards. Metal dome is widely used in electronic equipment, automobiles, medical equipment and other fields due to its conductivity and elasticity.

What is metal dome production?

Metal dome production is the process of creating tactile components used in electronic circuits. These domes are thin, metallic elements that act as switching mechanisms. When pressed, they collapse slightly and then bounce back, giving that crisp tactile feel. This action makes or breaks a circuit, allowing a signal to pass through.

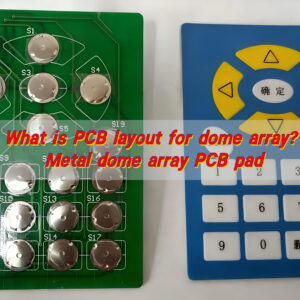

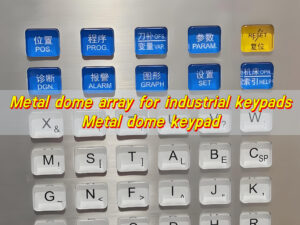

These domes are often found in membrane switches, remote controls, medical devices, and keypads. They’re reliable, durable, and incredibly precise. They may be small, but their role is massive.

How are metal domes manufactured?

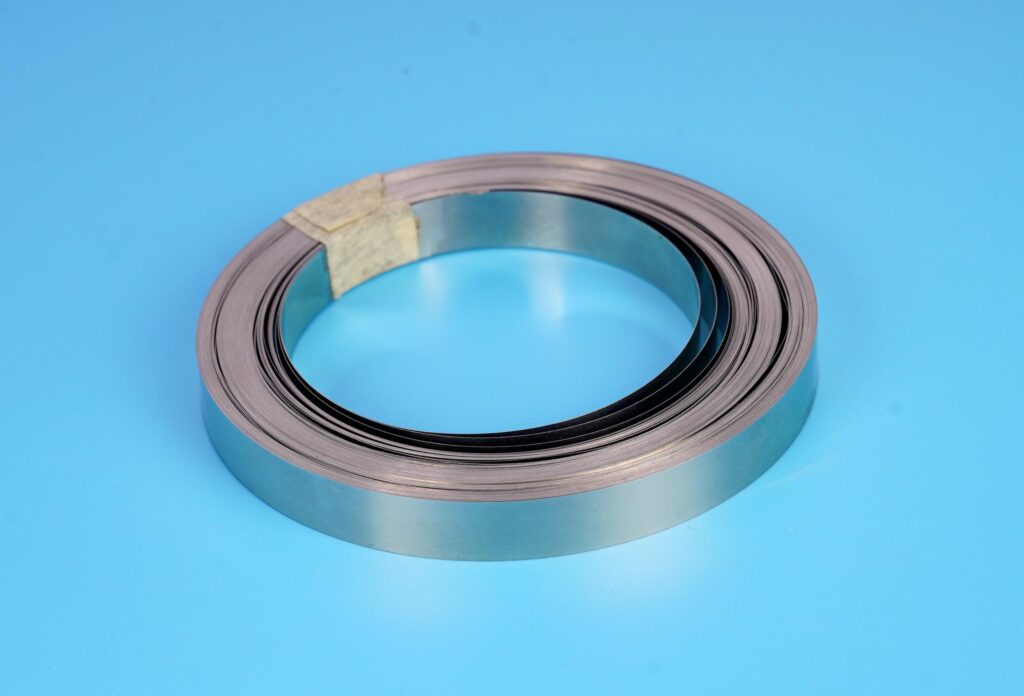

The creation of a metal dome begins with a precise combination of materials, machinery, and human expertise. The core idea is to stamp a metal sheet—usually stainless steel or other spring materials—into a dome shape. This involves special dies and high-pressure tooling. The accuracy in shape, size, and curvature is critical. Even a small deviation can affect the switch’s feel and performance.

Each dome must be perfectly formed, clean, and free of defects. That’s why top metal dome manufacturers put their products through strict quality control.

How does the metal dome production process work?

The metal dome production process is a sequence of careful steps that ensure each dome performs flawlessly.

First comes the material selection. The quality of the raw metal directly affects the dome’s reliability. Next, the metal goes through a flattening process. This ensures an even thickness.

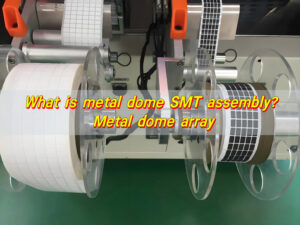

The stamping step comes after. Using precision dies, the machine presses the metal into dome shapes. The dimensions, including diameter and dome height, are strictly controlled.

After shaping, the domes are cleaned. This removes any debris or oil that may have stuck during production. Then comes the surface treatment—some domes require additional coatings for better conductivity or corrosion resistance.

Finally, inspection. Each dome is tested for shape, spring force, and click response. Only the ones that meet all standards make it to the packaging phase.

What are the key steps in metal dome production?

- Material Preparation: Stainless steel or alloy sheets are selected and cut to precise sizes.

- Stamping/Forming: High-pressure stamping tools shape the sheets into dome structures.

- Cleaning: Ultrasonic cleaning ensures no dust, oil, or particles remain.

- Surface Treatment: Domes may get plated with gold, nickel, or other coatings.

- Testing and Inspection: Force testing machines measure the tactile response. Visual inspection confirms dome symmetry and quality.

- Packaging: Domes are arranged on adhesive PET sheets or bulk-packed based on client needs.

Every step matters. A minor flaw in forming or material can lead to poor performance or failure. That’s why reliable production processes are non-negotiable.

What materials are best for metal dome production?

The heart of every dome is its material. Stainless steel is the most common. It’s flexible, durable, and resists corrosion. Different grades (like SUS301 or SUS304) offer varying strength and lifespan.

Some custom applications need gold-plated or nickel-plated domes for better conductivity. Others might require thicker domes for a stronger tactile response.

When considering custom production metal domes, the right material should match the application’s environment—whether it’s high humidity, temperature swings, or electrical needs.

Do different shapes affect metal dome production?

The shape of the dome changes how it behaves when pressed.

There are several popular types:

- Four-leg domes – stable and widely used in consumer devices.

- Tri-leg domes – good for narrow spaces.

- Round domes – smooth, centralized feedback.

- Oval domes – flexible, great for specific designs.

Each shape requires a different stamping die and production technique. Custom shapes also require custom dies. This can increase cost but gives unmatched precision.

In short, the shape impacts everything—from tactile feel to lifespan. Choosing the right shape is just as important as selecting the material.

What are the benefits of metal dome switches?

Metal dome switches are highly responsive. They give tactile feedback with every press. That means users know when a button has been activated. This feedback reduces errors, improves speed, and enhances satisfaction.

They’re also reliable. A quality metal dome can last over one million cycles. That’s years of use without failure.

They’re small, too. You can pack many switches into a compact area—perfect for handheld or medical devices.

Moreover, they’re flexible in design. Whether you’re creating a rugged control panel or a sleek remote, domes can adapt. In short, metal dome switches deliver reliability, tactile pleasure, and long life.

What makes a good metal dome manufacturer?

A great metal dome production factory focuses on quality, not just quantity. Look for companies that:

- Use certified raw materials

- Maintain tight production controls

- Offer a wide range of dome sizes and shapes

- Provide testing reports and quality documentation

- Accept custom dome production requests

- Communicate clearly and deliver on time

Also, check how long they’ve been in the business. Experience matters. A veteran team will know how to handle custom requests, avoid common issues, and ensure each batch is flawless.

Why trust BEST Technology for metal domes?

When it comes to metal dome production, BEST Technology stands out. With nearly two decades of experience, we’ve perfected the craft.

Our metal dome production process is built on precision, innovation, and quality. Every dome that leaves our facility meets international standards.

We offer full customization. Need a dome with unique force feedback? Want specific plating for better performance? We can do it.

BEST Technology’s team doesn’t just follow trends, but also sets them. From state-of-the-art stamping machines to advanced testing systems, we invest in top-tier tools to ensure every dome performs perfectly.

Clients from around the world trust our expertise. Our products are used in medical instruments, consumer electronics, industrial panels, and more.

Our team listens. We respond. We adjust production for each customer’s needs. If you are looking for the best metal dome, then best technology is your best choice.

Conclusion:

Metal dome production is more than just stamping metal—it’s the science and art of making every click matter. From raw materials to finished switches, each stage must be precise. The choice of shape, material, and manufacturer can make or break your device’s performance.

Choosing the right partner is key. BEST Technology brings unmatched expertise, care, and commitment to quality. Our domes don’t just perform—they impress.

Want metal domes you can trust, designed just for you? Reach out to sales@metal-domes.com