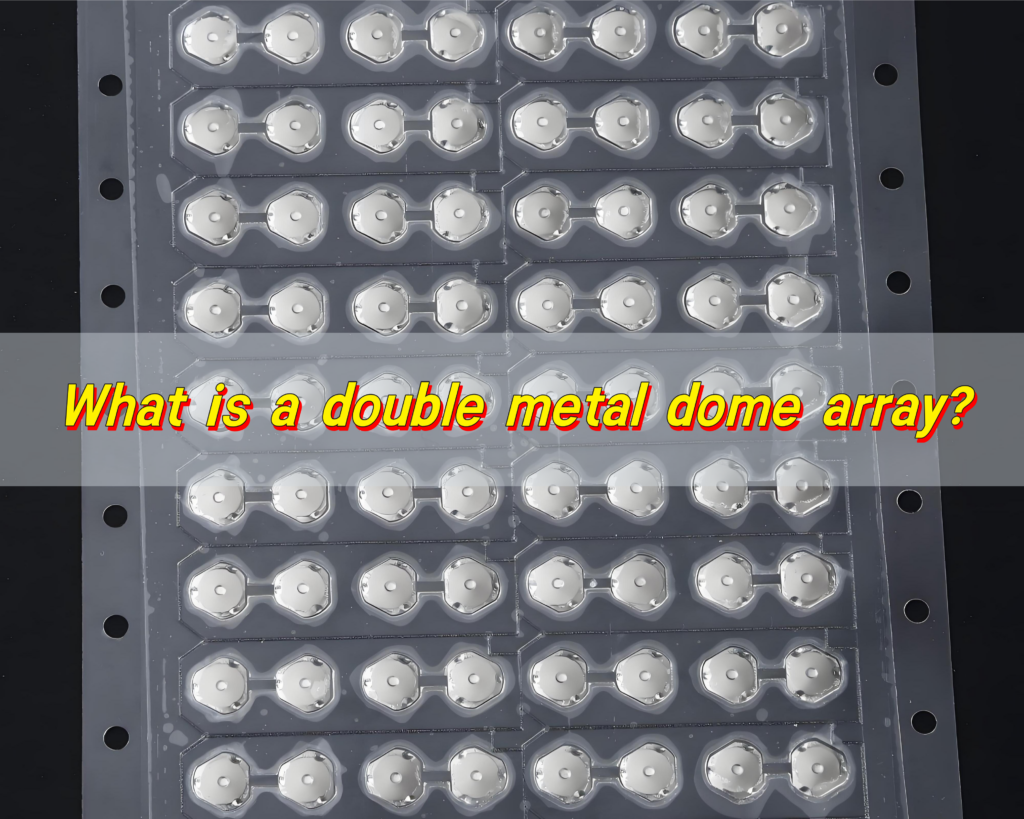

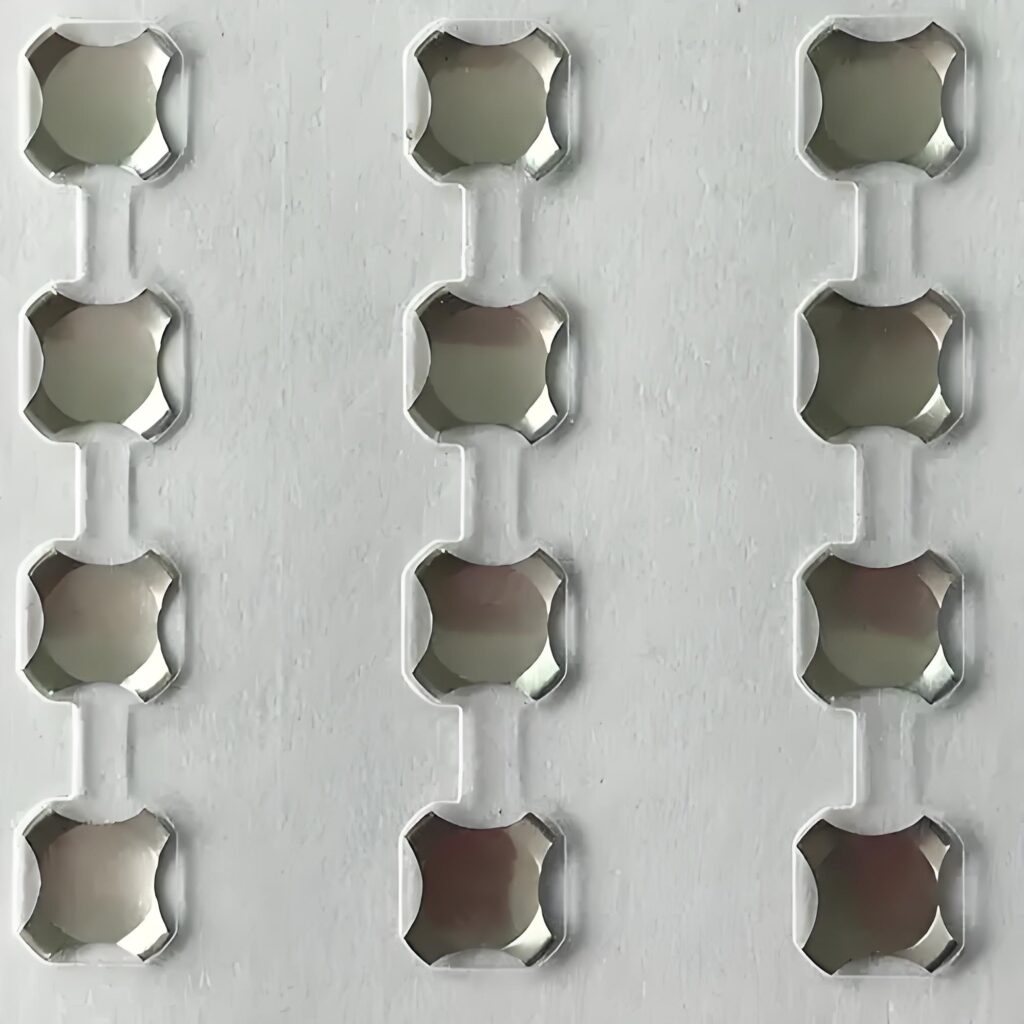

The double metal dome array is a sophisticated switch design that adds a layer of Maylar (polyester film) under a layer of metal dome. This structure not only retains the advantages of a single-layer dome switch, but also disperses the pressing force through the gasket, reducing the load on the metal dome, thereby reducing the risk of failure caused by excessive deformation.

What is a double layer dome array?

A double metal dome array, often referred to as a double metal dome sheet, is an advanced tactile switch design. Unlike the conventional single dome structure, this version integrates two metal domes layered vertically. Both are placed under a Mylar (PET) film, but here’s the twist—the spacer is positioned beneath the dome contacts, not above or between layers.

It might resemble a single-layer structure. But the layered design changes everything. The dual domes interact to create an exceptionally crisp, responsive press—every time.

These are intelligently built beneath the domes and act much like the air holes found in single-layer types. When a dome is pressed, air flows through these channels to deliver a cleaner, more defined click.

These air paths serve two additional purposes:

- Protecting the PET film from wear caused by dome contact burrs

- Blocking dust from entering the internal layers of the switch.

How does a double layer dome array switch work?

The working principle of the double-layer dome array switch is as follows: This switch consists of two layers of metal dome, the dome contacts of the first layer of dome are located under the Maylar (polyester film), and the second layer of dome(gasket) is located under the contacts of the first layer of dome. An airway is designed under the dome contacts.

When the user presses the dome contacts, the airway adjusts the pressure, provides a good click feeling, and reduces the possibility of the PET film being damaged by the burrs of the metal dome contacts, while preventing dust from entering the PET film.

When the button is pressed, the contacts of the first layer of dome move downward and contact the second layer of dome to form a circuit conduction. The airway helps to buffer the pressing force and provide clear tactile feedback. After releasing the button, the dome returns to its original state and the circuit is disconnected. This design combines the advantages of double-layer dome to ensure the stability and durability of the switch, while improving the user experience and the protection performance of the device through the setting of the airway.

Why use a double metal dome instead of a single dome?

- Superior Click Feel: The dual-dome structure delivers a sharper, more confident tactile response.

- Improved Actuation Force: The added resistance reduces accidental presses, making the switch more reliable in critical applications.

- Better Debris Protection: Thanks to the smart layout and built-in air paths, the design keeps dust and other particles from interfering with the internal mechanism.

Where are double metal dome switches used?

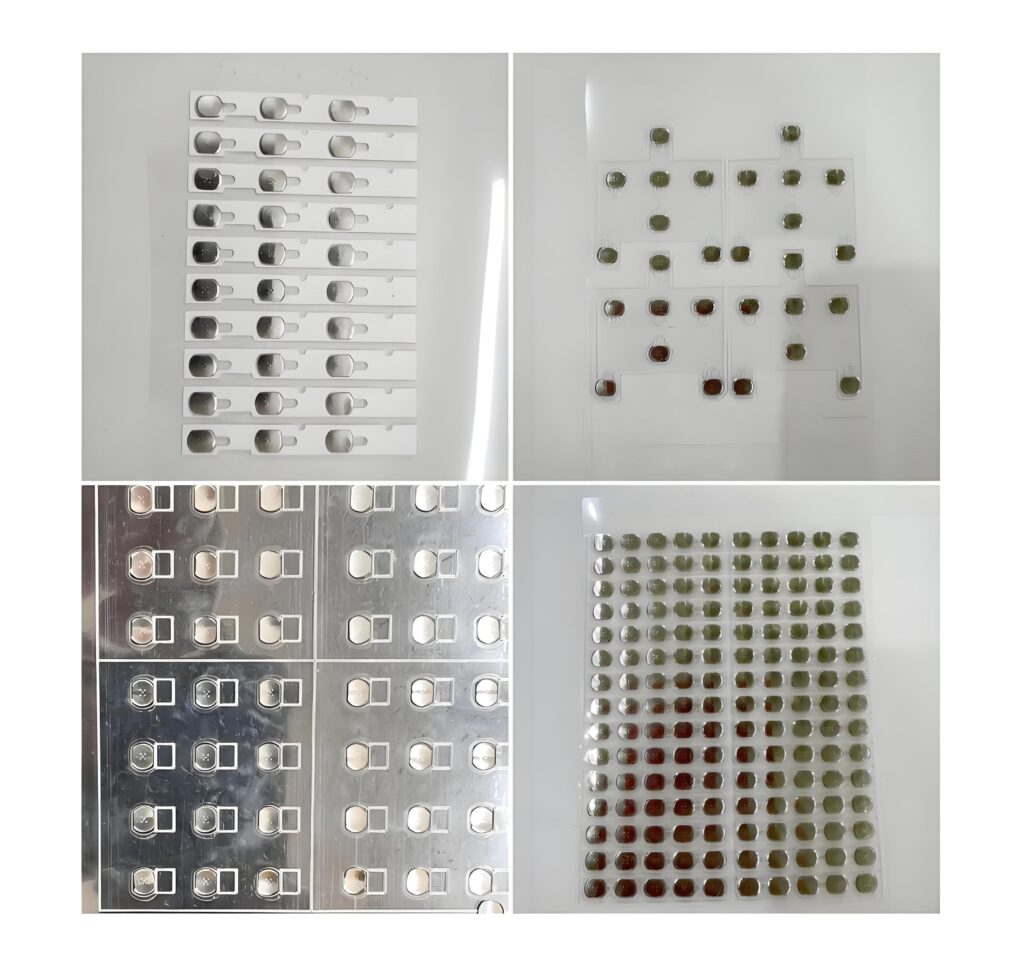

Double-layer spring array switches are mainly used for:

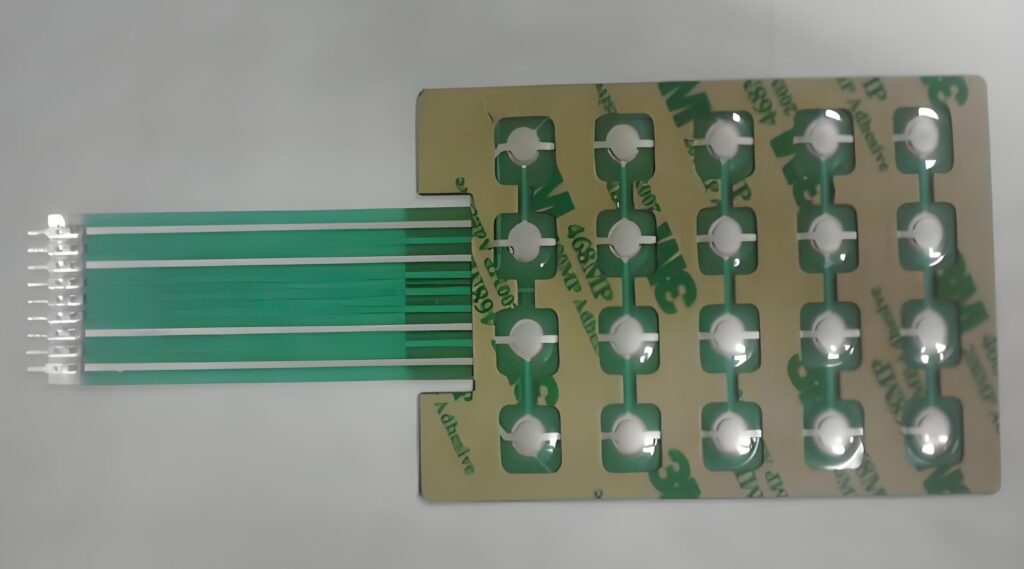

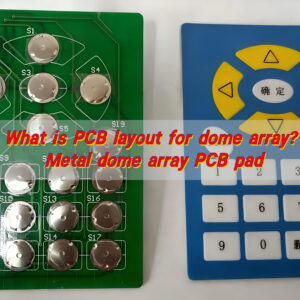

- Membrane switches: provide good tactile feedback and circuit connection, widely used in various membrane switch devices.

- PCB circuit board: realize circuit on-off control in PCB circuit board, suitable for various electronic devices.

- FPC flexible circuit board: provide reliable connection and control functions in flexible circuit board.

- Electronic devices: such as smart phones, tablets, laptops, etc., used to realize key functions and circuit control.

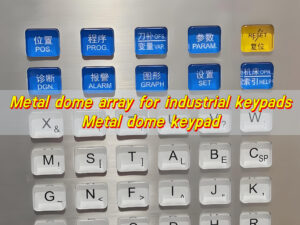

- Industrial control: used for control panels and operation interfaces in industrial equipment, providing stable performance and long life.

- Smart devices: such as smart home control panels, smart wearable devices, etc., used to realize user interaction and device control.

How does a snap dome switch compare to a metal dome switch?

A metal dome switch refers to any switch that uses a metal dome as a contact element. Meanwhile, a snap dome switch highlights the tactile sensation—the “snap”—you feel when pressing the dome.

In practice, many metal dome switches are also snap dome switches. But the strength and sharpness of the snap vary depending on the dome’s shape, material, and construction.

With a double metal dome array switch, you get the best of both. It’s a metal dome by design and a snap dome in function—only better. Two domes mean a richer snap, a faster rebound, and greater durability.

What’s special about Best Technology metal dome arrays?

At Best Technology, we pride ourselves on building dome arrays that deliver performance you can feel—and reliability you can trust.

Here’s what sets Best Technology metal dome arrays apart:

- Precision Manufacturing: Every dome is engineered for consistent actuation force, size, and snap ratio.

- Customizable Designs: Whether you need a specific shape, force level, or dual-layer configuration, we tailor solutions to fit your exact application.

- Advanced Material Quality: We use only high-grade stainless steel and PET films to ensure durability and performance.

- Protective Layout with Air Paths: Our double dome arrays are designed with air channels that boost tactile feel, prevent film damage, and reduce dust ingress.

From prototyping to mass production, we help customers across industries build better products, faster.

Are double dome arrays better for durability?

Double-layer dome array switches are generally better for durability for the following reasons:

- Structural design: Double-layer dome array switches add gaskets and airway designs to single-layer domes. The gasket is located below the dome contact, which can effectively disperse the pressing force and reduce the load on the dome, thereby reducing the risk of failure due to excessive deformation.

- Pressure distribution: The double-layer design distributes the pressing force between the two dome layers instead of concentrating it on a single dome.

- Protection mechanism: The airway design not only enhances the click feeling, but also plays a protective role. It reduces the direct contact between the PET film and the metal dome contact, reduces the risk of damage caused by friction or burrs, and prevents dust and other particles from entering the switch, further extending the service life of the switch.

- Stability: Double-layer dome array switches show higher stability in frequent operation and long-term use. Due to the more uniform pressure distribution, the deformation and recovery process of the dome is smoother, reducing local wear and fatigue failure caused by stress concentration.

- Practical application performance: In practical applications, the double-layer dome array switch can withstand higher frequency operations and harsher environmental conditions. This design is particularly suitable for equipment that requires high durability and reliability, such as industrial control panels, medical equipment, smart home devices, etc.

In summary, the double-layer dome array switch is superior to the single-layer dome array switch in durability and reliability through its unique structural design and multi-layer protection mechanism, and is particularly suitable for use in high-frequency operations and harsh environments.

How does a metal dome switch improve user experience?

The tactile feedback of a switch creates a psychological connection between the user and the device. When it’s smooth, consistent, and sharp—users trust the hardware more.

And when you double the dome, the experience becomes even more engaging:

Clearer tactile signal?Reduced false presses?Enhanced control and accuracy.

Conclusion:

The double metal dome array is more than a switch—it’s a solution. From smoother clicks and longer life to smarter air path design, it delivers unmatched tactile control.

And when it comes to quality, precision, and customization, Best Technology stands at the forefront. We specialize in building dome arrays that not only meet industry demands but exceed them.

Contact us today at sales@metal-domes.com to get started on your custom dome solution.