Have you ever faced such situation that your tactile Switches does not return back when press down it? It is what we call “dead key” of metal dome. It is fatal for metal dome, for it will lead that the whole product cannot work as normal. So why does the dead key occur? Can we solve this problem? Today, we will introduce the factors that cause the issue and how to solve it.

What dead key is?

The dead key phenomenon, characterized by unresponsive or stuck keys, can have a detrimental impact on the performance of tactile switches. By understanding the underlying causes and implementing effective solutions, manufacturers can ensure their products deliver a seamless user experience.

Reasons and solutions for dead key

Below are the common reasons and solutions for dead key, hope that will make sense for you.

1.Limited Lifespan of Tactile Switches or Metal Dome

Tactile switches contain metal domes, commonly referred to as keycaps or key domes, which have a finite lifespan. Over time, repeated presses can cause the key domes to wear out, resulting in dead keys. To address this, designers should pay more attention to the long lifespan of the metal dome, and selecting experienced manufacturers who can supply high-quality key domes that can withstand a substantial number of presses without compromising their responsiveness.

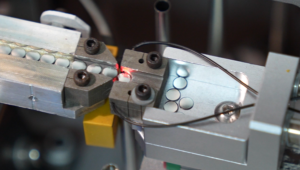

2.Insufficient Key Dome Rebound

The rebound force of a key dome is crucial for its proper functioning. If the rebound force is too low, the key dome may fail to return to its original position, leading to dead keys. So when the dead key issue occurs, we should prioritize optimizing the design and manufacturing process to ensure that key domes possess adequate rebound capability, enhancing the longevity and responsiveness of the switches.

3.Excessive Force Applied to Tactile Switches

Applying excessive force while pressing keys can cause damage to the key domes, resulting in dead keys. Educating users about the appropriate force required for key presses can minimize the occurrence of this issue. Additionally, it is needed to strive to reinforce the structural integrity of the switches to withstand reasonable force without impairing their functionality.

4.Excessive Travel Distance during Key Presses

Tactile switches have a specific travel distance, which is the distance the keycap travels when pressed. If the travel distance is too large, dead keys may occur when the keycap bottoms out and fails to register subsequent presses. Designers should carefully determine the optimal travel distance, balancing user comfort with reliable key registration.

5.Inadequate Ventilation in Key Domes

Proper ventilation is essential for effective key dome performance. Without adequate ventilation, air trapped beneath the key dome during a press cannot escape efficiently, leading to dead keys. If you don’t know how to design the vent hole, welcome to contact us for consulting.

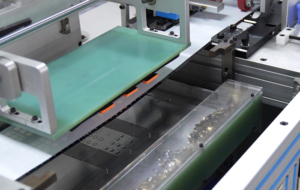

6.Optimal Gap between Silicone Keypads and PCB

When utilizing silicone keypads in conjunction with printed circuit boards (PCBs), maintaining an appropriate gap between them is crucial. Insufficient gap spacing can restrict the movement of key domes, resulting in dead keys. Designers should carefully consider the dimensions and ensure an optimal gap to allow for smooth and unobstructed key presses.

Overcoming the dead key phenomenon in tactile switches is essential for providing users with an enhanced and seamless typing experience. Through continuous improvements in design, materials, and manufacturing processes, the dead key problem can be overcome, enabling users to enjoy smooth and consistent key registration, ultimately enhancing their overall satisfaction with the product.