SMT electronic components are tiny parts mounted directly onto a PCB surface instead of using through-hole leads. This design makes devices smaller, faster, and more efficient. These components include resistors, capacitors, ICs, LEDs, sensors, and even SMD dome switches.

What Are SMT Components?

SMT components are small electronic parts designed for “surface mount” placement. They sit directly on the surface of a PCB instead of passing through holes. This design changes everything. It saves space. It speeds production. And it increases reliability by reducing mechanical stress on the board.

These components come in many types. You see resistors, capacitors, diodes, transistors, ICs, sensors, LEDs, and more. Every piece has a job. And each one works together to form a complete circuit.

What Is SMT in Manufacturing?

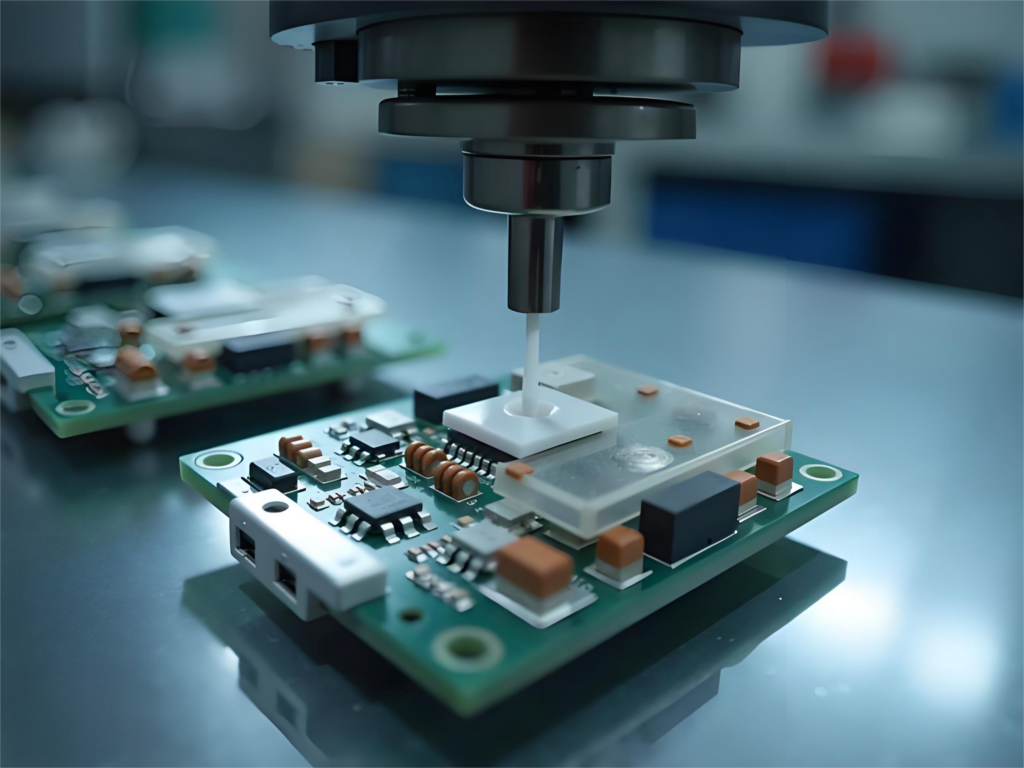

SMT in manufacturing refers to the full process of assembling SMT components onto PCB surfaces. It is a system. And a very smart one.

This system includes several key steps such as solder paste printing, pick-and-place machine mounting, reflow soldering, inspection, and final testing. Each step is precise. Each step requires accuracy.

The pick-and-place module is the star of this manufacturing process. It moves fast. Sometimes it can place tens of thousands of components per hour. This speed pushes production to new heights. It reduces cost and ensures uniform quality.

Another important part is reflow soldering. Here, the PCB enters a hot zone where solder paste melts and creates a strong joint between the pad and the component. After cooling, the result is a solid, lasting connection.

So, SMT in manufacturing means more speed, more consistency, and more output.

What Is SMT Used For?

SMT is used in nearly every modern electronic product. The versatility is extreme. And the applications continue to grow.

You will find SMT in:

- Smartphones and tablets

- Smartwatches and wearables

- Medical monitoring devices

- Automotive sensors and controls

- Industrial control modules

- Communication devices

- Consumer electronics

- LED lighting systems

- Gaming accessories

- Home appliances

- IoT devices

- Security and access systems

- Aerospace tools

- Robotics

- Telecom equipment

This list goes on and on. The point is clear: SMT technology is everywhere. It drives innovation. It makes products smaller and more elegant.

Because of its compact form and reliable structure, SMT electronics help designers unlock features that were never possible in older through-hole designs.

Advantages and Disadvantages of SMT

Although SMT technology is powerful, it often has some advantages and disadvantages.

Advantages of SMT

- Smaller and lighter designs: SMT components take less room. They reduce weight. This makes devices feel modern and compact.

- Faster production speed: Pick-and-place machines increase efficiency and allow high-volume projects without limitations.

- Strong performance: Because SMT joints are small and stable, the electrical performance tends to be consistent and reliable.

- High density and more functions: A design can include more features without increasing PCB size.

- Lower production cost in large batches: As production scales, the cost drops and becomes extremely competitive.

- Better vibration resistance: Since components sit close to the PCB, the structure withstands shock better.

- Improved automation: SMT works well with automated lines, reducing manual labor and increasing consistency.

These advantages fuel the global demand for SMT electronics manufacturing.

Disadvantages of SMT

- Manual repair can be harder: Components are small. This makes rework more delicate.

- High heat during reflow may affect some parts: Heat-sensitive components need special handling.

- Not ideal for high mechanical stress points: Some connectors or large transformers still prefer through-hole for stability.

Although these disadvantages exist, they are minor compared to the huge benefits.

What Is the Difference Between SMT and SMD Components?

Many beginners confuse these two terms. And it is normal. They are related but not the same.

- SMT (Surface Mount Technology)

SMT describes the process of mounting components on the PCB. It includes machines, workflows, soldering, and inspection.

- SMD (Surface Mount Device)

SMD describes the components themselves. An SMD component is designed to sit on the PCB without leads passing through holes.

In short:

- SMT = The method

- SMD = The parts used in that method

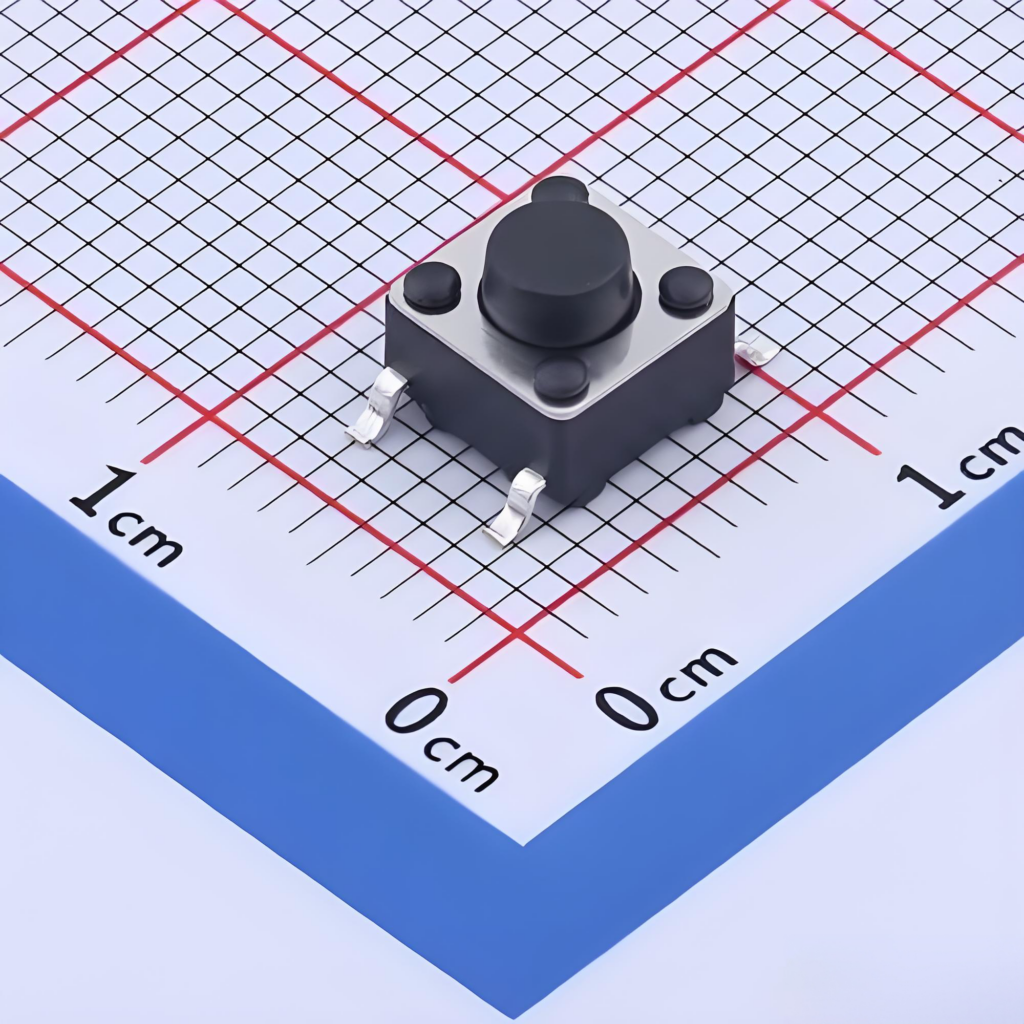

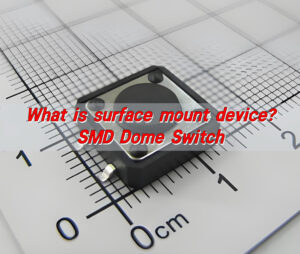

What Is an SMD Dome Switch?

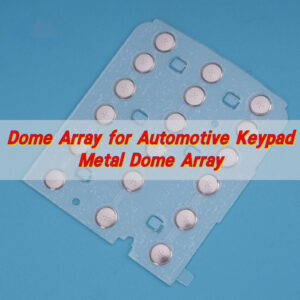

An SMD dome switch is a special type of tactile switch used in keypads and interface devices. Instead of traditional buttons, it uses a metal dome as the switching element. When pressed, the dome snaps and completes a circuit. This action gives a crisp, responsive feel.

The dome sits inside a switch housing or a metal dome array. The SMD version is created for SMT process lines. This means the dome switch sits on a PCB pad, and the reflow soldering secures it in place.

An SMD dome switch provides several great benefits:

- Clean tactile feedback

- Fast response

- Long lifespan

- Stable actuation force

- Slim structure

- Great for wearable devices

- Easy integration in compact layouts

These switches excel in areas where tactile feel matters. People love the “snap” sensation. It gives confidence that the input is accurate.

An SMD dome switch is often used in remote controls, communication equipment, handheld devices, medical tools, and consumer electronics. Because they are lightweight and slim, they fit perfectly into modern compact designs.

When Should You Use SMD Dome Switches in SMT Designs?

When to use SMD dome switches depends on your design goals. However, they are particularly suitable in the following situations.

- 1. When tactile feedback is required

If your product needs a clear snap feel, the SMD dome switch is ideal.

- 2. When the design space is tight

The structure is ultra-thin. You can place them in very small areas without losing performance.

- 3. When the device must stay lightweight

Wearable, portable, and handheld tools benefit from the low profile and low weight.

- 4. When long life is important

SMD dome switches can provide hundreds of thousands or even millions of cycles.

- 5. When the product needs clean, modern aesthetics

They help designers create smooth and flat interfaces.

- 6. When the PCB is assembled through SMT technology

SMD dome switches fit seamlessly into SMT production lines. This helps reduce manual assembly time and improves consistency.

- 7. When you want low-cost production with high value

Their price-to-performance ratio is amazing. It gives more value to the entire project.

Overall, SMD dome switches match perfectly with SMT components. When tactile clarity and reliability matter, they are one of the smartest choices.

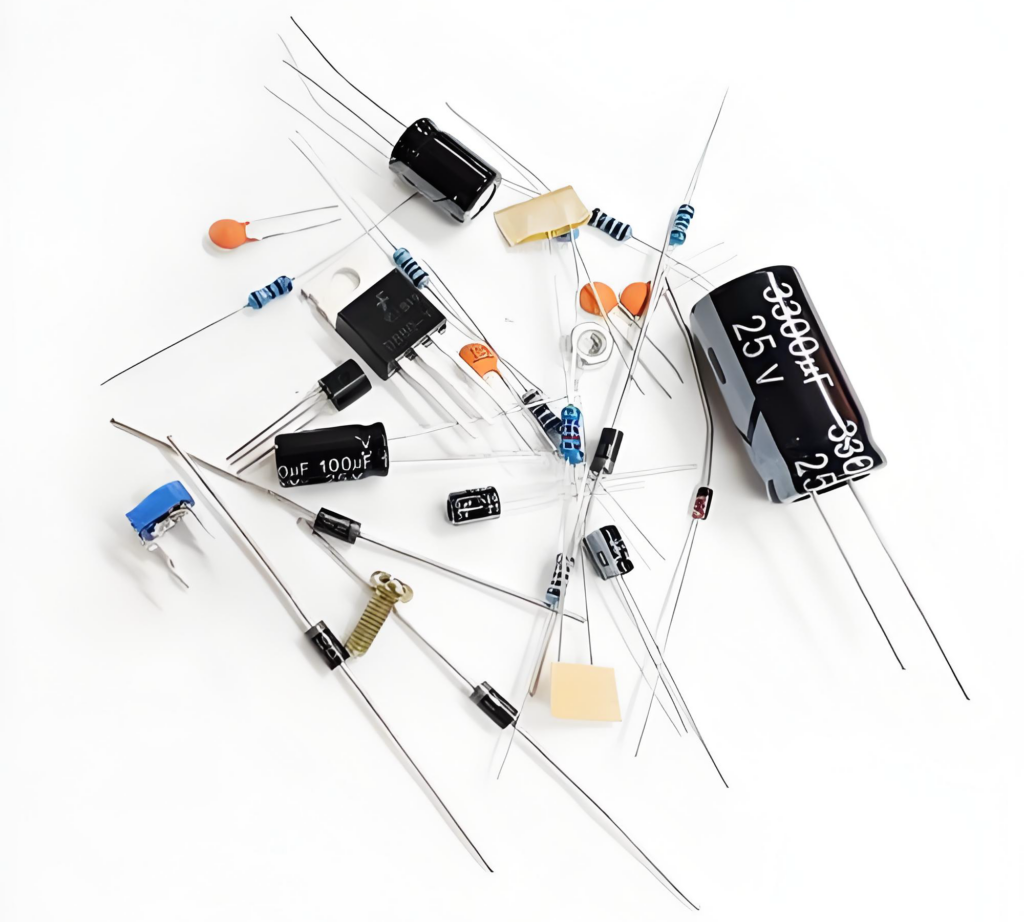

Which SMT Components Are Most Common? (SMT Components List)

Below is a helpful list of common SMT electronic components. These parts appear in most SMT electronics manufacturing projects.

- Resistors: They control current. They manage signals. SMT resistors come in many sizes such as 0201, 0402, 0603, 0805, 1206, and more.

- Capacitors: They store energy. They filter noise. Ceramic capacitors are the most common.

- Diodes: These include rectifier diodes, Zener diodes, and switching diodes. They control current direction and help protect circuits.

- Transistors: SMT transistors handle amplification and switching tasks. They are essential building blocks.

- Integrated Circuits (ICs): These mini chips hold complex functions such as processing, memory, logic, and sensing.

- Oscillators and crystals: They provide timing and synchronization.

- LEDs: Compact lighting solutions used in displays, indicators, and backlighting.

- Inductors: Used for power conversion, filtering, and energy storage.

- Sensors: Pressure, temperature, motion, humidity, and many other types.

- Connectors and terminals: Slim SMT connectors support high-speed data and compact structures.

- SMD switches: Including SMD dome switches, tactile switches, and low-profile buttons.

- Microcontrollers: Small integrated controllers for automation and logic control.

- Power components: MOSFETs, regulators, DC-DC modules, and power management chips.

- RF components: Used for wireless signals and communication modules.

This SMT components list shows how wide the range is. Every PCB uses a combination of these parts.

Conclusion:

SMT electronic components form the heart of modern electronics. They power our daily devices and make advanced technology possible.

If you want reliable SMT components, metal dome switches, or metal dome arrays, you can always reach out for more details or technical support. Contact: sales@metal-domes.com