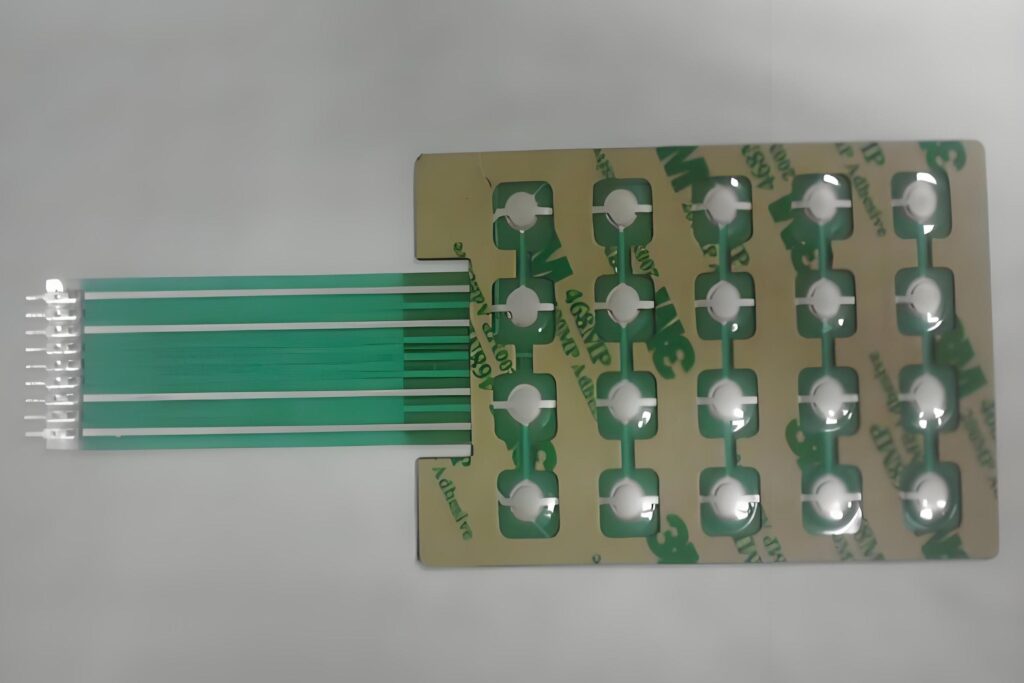

Metal dome membrane switch is a switch that combines metal dome and membrane technology. It is composed of multiple layers of film, including panel, conductive layer, insulating layer and circuit layer. The metal dome is installed at a specific position of the film. When the button is pressed, the metal dome is deformed by pressure and contacts the circuit layer to achieve circuit conduction; when the button is released, the dome returns to its original state and the circuit is disconnected.

What is a metal dome membrane switch?

Metal dome membrane switch is a highly responsive interface that combines thin, flexible layers with a spring-like dome structure. The core of the design is the metal dome—a tiny precision-formed disk that responds to pressure.

When pressed, it collapses with a distinct tactile snap, completing the circuit beneath it. Release the pressure, and it pops back up, resetting for the next activation.

The metal dome offers exacting control, ideal for industries where one missed signal could mean serious issues—like in medical equipment, aerospace interfaces, or military tools.

How does a tactile metal dome switch work?

These domes are made from ultra-thin stainless steel, designed to flex and return with precision. The switch stack typically includes a top graphic layer, a spacer, a circuit layer, and beneath it, the tactile metal dome.

When you press down, the dome bends, making electrical contact with the circuit below. This touch completes the path, registering your action instantly. It lets users know their input has been received.

Every press feels the same. And every dome is engineered to last over a million actuations. It’s tactile, yes—but also exact.

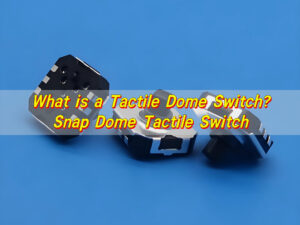

What makes snap dome switches so responsive?

Snap dome switches aren’t just responsive—they’re engineered to deliver performance with precision. What sets them apart is how they respond to pressure. The moment your finger presses down, the dome collapses sharply. It creates a fast, crisp click.

The shape and size of each snap dome influence its feel. Triangles offer stronger resistance. Four-leg domes balance firmness with flexibility. Round domes give lighter touch response.

Materials also matter. Stainless steel keeps its form. Special coatings like nickel or gold add conductivity and protection. That’s what gives each dome its unmatched response time—and its long life.

Why use metal domes in membrane panels?

Because metal domes bring clarity, strength, and performance. In a membrane switch, user interaction must be reliable. That’s where metal domes excel.

They add a responsive layer that boosts confidence. Press, feel the snap, release. No lag. No delay. Just feedback.

And they’re built to last. While rubber options may fade, metal domes resist fatigue. They hold their shape through heat, pressure, and time. Their low profile allows slimmer, sealed designs—perfect for harsh environments.

Customization is another win. Choose actuation force, dome shape, and contact style. Combine performance with precision. That’s what metal domes bring to every membrane switch panel.

What are membrane switches used for?

Membrane switches power the interfaces you touch every day. They’re in hospital monitors, ATM keypads, industrial controls, home appliances, and even outdoor kiosks.

Why? Because they’re slim, sealed, and easy to clean. They resist moisture, dirt, and chemicals—yet they’re responsive and reliable.

When combined with metal domes. You get the durability of sealed electronics with the satisfying feel of tactile feedback. Their compact construction makes them great for portable devices. Their long life makes them perfect for high-use areas.

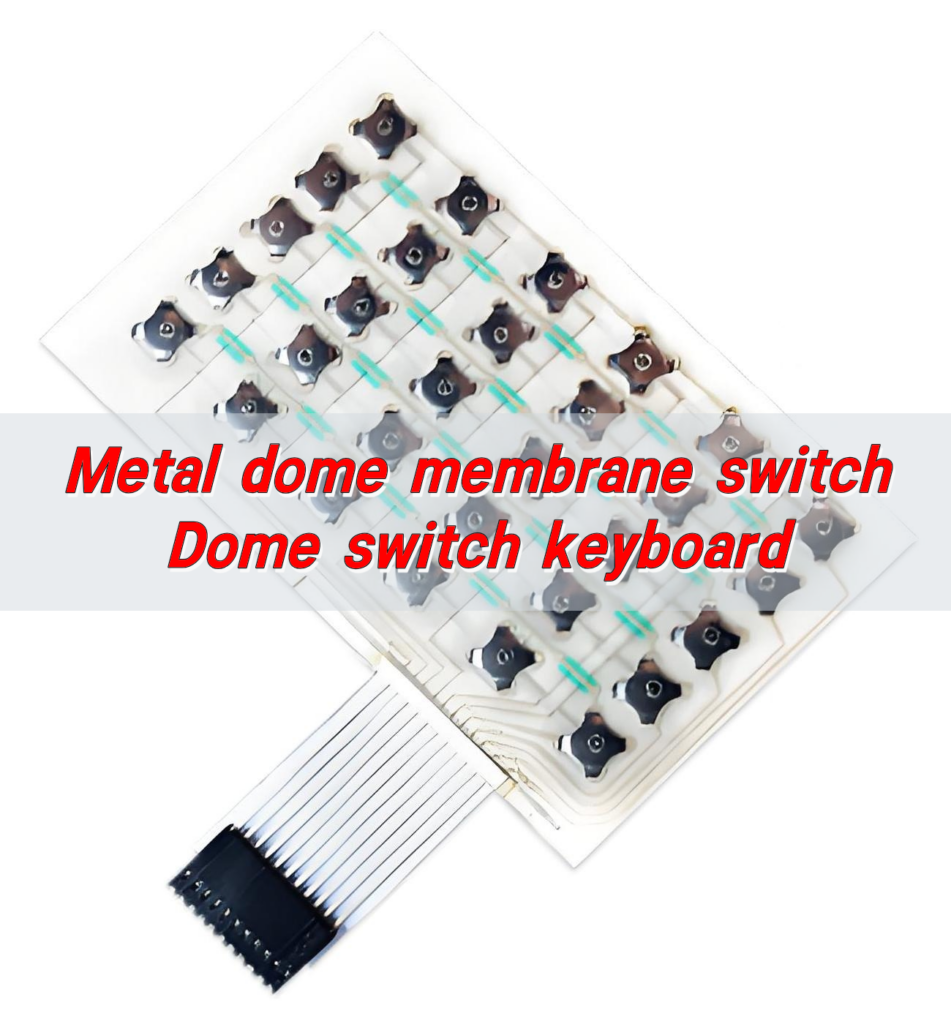

What is a dome switch keyboard?

Dome switch keyboard is a collection of dome switches arranged in a defined layout—also called a dome array. Each button on the panel activates a metal dome below it. Together, they create a fast, tactile, and rugged interface.

These keyboards are often custom-built. They are applied in outdoor terminals, factory equipment, hospital tools. Instead of mechanical keys, the interface stays sealed and safe from dust and water.

Press a key, and the dome clicks back. The feedback is instant. It’s built for function but doesn’t compromise on feel.

What are rubber dome switches?

Rubber dome switches use molded rubber pads instead of metal domes. These pads deform under pressure, triggering the switch. They’re soft and quiet.

But softness comes with trade-offs. Over time, the rubber loses shape. Presses become less consistent. The feel gets mushy. And the lifespan is shorter—usually a few million actuations at best. They’re easy to produce and assemble.

Rubber dome vs mechanical: Which lasts longer?

Mechanical switches are known for endurance. Each switch has its own spring and housing, designed for heavy use. Some last over 50 million keypresses. But they’re big, noisy, and not sealed.

Rubber domes, on the other hand, wear down quicker. The rubber becomes soft. The click disappears. They’re cost-effective—but not built for the long haul.

Metal dome membrane switches hit the sweet spot. They combine tactile feel with slim design and high durability. Many last over 1 million actuations, even under pressure or in extreme environments. They’re lighter than mechanical options, but stronger than rubber.

Conclusion:

Metal dome membrane switches deliver powerful tactile feedback, high durability, and precision response—making them ideal for demanding applications like medical devices, industrial control panels, and custom dome switch keyboards. Unlike rubber domes, they maintain consistent performance over millions of actuations.

Looking for a reliable supplier? Contact sales@metal-domes.com today. We’ll help you build the switch solution your application truly deserves.