What is an emergency stop push button?

An emergency stop push button is a dedicated safety control designed to immediately stop a machine or system when a hazardous situation appears. Its sole purpose is protection. When pressed, it overrides the standard control logic and brings equipment to a safe state as fast as possible.

In industrial environments, the emergency stop push button is often the last line of defense between a machine and the people working around it. It is installed where operators can reach it quickly, even under stress. The action is simple and direct. Pressing the button interrupts power or control signals so motion, heat, pressure, or electrical output is halted.

From a functional point of view, an emergency stop push button is part of a broader safety system. It often works with safety relays, safety PLCs, or dual-channel circuits. The button itself is a human interface, but its reliability affects the entire safety chain. A poorly designed or poorly installed emergency stop push button undermines the system it is meant to protect.

In modern factories, these buttons are used on CNC machines, conveyors, packaging lines, robotic cells, elevators, medical equipment, and laboratory systems. Even smaller machines benefit from a properly implemented emergency stop push button because accidents are not limited to large installations.

What are the different types of emergency stop buttons?

Emergency stop buttons are not all identical. Different machines, environments, and risk levels require different designs.

The most common types of emergency stop buttons include:

- Mushroom-head emergency stop button

This is the most widely used design. The large, round actuator is easy to strike with a hand, elbow, or knee. Its size and shape make it ideal for rapid activation in urgent situations.

- Push pull emergency stop button

This type is pressed to stop the machine and pulled outward to reset. Push pull emergency stop buttons are commonly used on general industrial machinery.

- Twist-release emergency stop button

After activation, the actuator must be rotated to reset. This deliberate action helps prevent accidental restarts and is often preferred in automated lines and robotic systems.

- Key-release emergency stop button

Resetting requires a dedicated key, giving restart authority only to trained personnel. This type is commonly used in maintenance areas or high-risk zones where controlled access is essential.

- Cable-pull emergency stop switch

Instead of a single actuator, a cable runs along conveyors or long production lines. Pulling the cable at any point triggers the emergency stop, making it suitable for extended or hard-to-reach equipment.

- Palm-operated or foot-operated emergency stop buttons

These are used in specialized applications where hands may not be free or where ergonomic considerations require alternative activation methods.

Although the activation method varies, the underlying principle remains the same. Each emergency stop button must provide fast and reliable interruption of hazardous motion or energy. Selection should be based on accessibility, environment, and operational workflow rather than appearance alone.

When should you push the E-stop button?

The emergency stop button should be pushed whenever a situation presents an immediate risk to people, equipment, or the surrounding environment. It is intended for abnormal and dangerous conditions, not for routine stopping or process control.

Typical scenarios include unexpected machine movement, jammed material that creates a hazard, a person entering a restricted zone, electrical faults, smoke, or abnormal noise that signals mechanical failure. In these cases, hesitation can increase damage or injury.

Training plays a major role here. Operators should be taught that it is always acceptable to press the emergency stop if they feel unsafe. There should be no penalty for caution.

It is also important to understand when not to use it. The emergency stop push button is not meant for normal shutdown at the end of a shift or for pausing production to make adjustments. Using it as a routine control can increase wear and create complacency, which reduces its impact in real emergencies.

In well-designed systems, pressing the emergency stop button triggers a defined safety response. Motion stops, energy is removed or reduced, and the system enters a safe state. Restart requires inspection and a deliberate reset process. This ensures that hazards are addressed before operation resumes.

In short, if there is doubt, press the button. Equipment can be repaired. Production can be restarted. Safety cannot be recovered once lost.

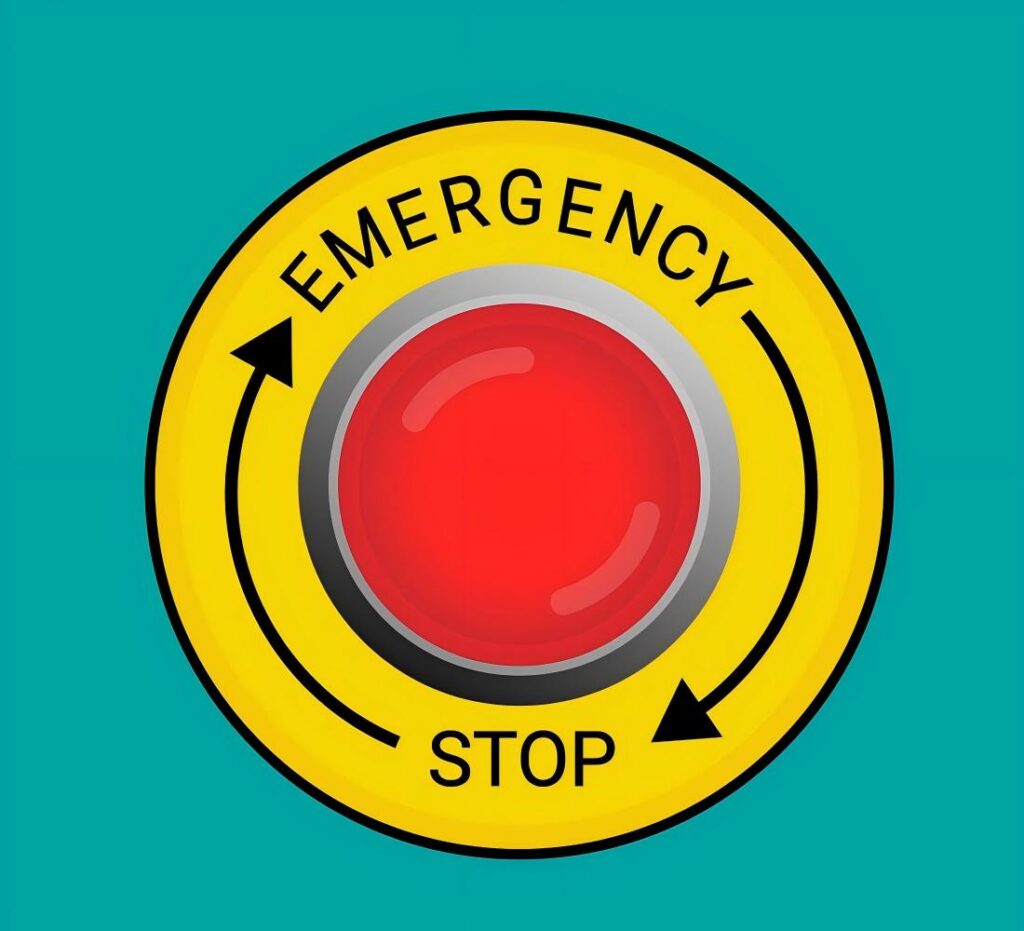

Do emergency stop buttons need to be RED?

Yes, emergency stop buttons are required to be red in most industrial standards, and this requirement exists for good reasons.

Red is universally associated with danger, stop, and warning. In a busy industrial environment, the emergency stop push button must stand out from all other controls. A red actuator against a contrasting background achieves this visibility.

Standards such as ISO 13850 specify that emergency stop actuators should be red, typically mounted on a yellow background. The yellow enhances contrast and helps the button remain visible even in poor lighting or cluttered panels.

Beyond compliance, red buttons also reinforce training. When people are taught to look for the red emergency stop push button, the lesson applies everywhere. This consistency saves time and reduces risk.

What are the requirements for an emergency stop button?

Emergency stop buttons are governed by clear functional and design requirements. These requirements ensure that the button performs reliably under all reasonable conditions.

- First, the emergency stop push button must be easily accessible. It should be within reach of the operator and not blocked by guards, doors, or equipment.

- Second, the action must be latching. When pressed, the button stays in the stopped position until it is intentionally reset. This prevents machines from restarting automatically after a brief interruption.

- Third, the contacts used in an emergency stop push button must be suitable for safety circuits. In most cases, this means normally closed contacts that open when the button is pressed.

- Fourth, the button must be robust. It should withstand mechanical impact, vibration, dust, moisture, and temperature variations typical of the application.

- Fifth, the reset action must be deliberate. Whether it is pull, twist, or key release, the reset should require a conscious decision. This ensures that the cause of the emergency stop is addressed before restarting.

- Finally, the emergency stop push button must not be used as a substitute for proper guarding or safe design. It is an additional protective measure, not the primary one.

Is the emergency push button NC or NO?

Emergency stop push buttons are typically wired using normally closed (NC) contacts. This choice is intentional and rooted in safety logic.

In a normally closed configuration, the circuit is complete during normal operation. When the emergency stop button is pressed, the circuit opens and signals the safety system to stop the machine. If a wire breaks, a terminal loosens, or the button fails internally, the circuit also opens. The system interprets this as a stop condition.

This behavior is known as fail-safe. It ensures that faults lead to a safe outcome rather than allowing operation to continue unknowingly. Normally open (NO) contacts do not provide this level of protection because a broken wire might go unnoticed.

Many emergency stop push buttons include multiple NC contacts. These can be wired in dual channels to safety relays or controllers. Redundancy increases reliability and helps meet higher safety integrity levels.

What is the difference between emergency stop and stop button?

The difference between an emergency stop button and a regular stop button lies in purpose, design, and system response. Although both can stop a machine, they are not interchangeable.

A stop button is part of normal operation. It is used to pause or end a process under expected conditions. It may be momentary, it may be normally open, and it often does not latch.

An emergency stop push button is designed for abnormal situations. It bypasses normal control logic and prioritizes rapid hazard reduction. The response is immediate and may be abrupt.

Physically, stop buttons are often smaller and may be green, black, or another neutral color. Emergency stop buttons are larger, red, and unmistakable.

What are two typical qualities for an emergency stop button?

Two defining qualities of an effective emergency stop push button are reliability and clarity. These qualities influence every aspect of its design and use.

Reliability means the button works every time it is needed. It activates under force, under stress, and under imperfect conditions. It maintains contact integrity over thousands of cycles. It resists environmental damage and mechanical wear. Reliability is not optional because failure during an emergency is unacceptable.

Clarity means the button communicates its function instantly. Its color, shape, size, and placement leave no doubt. Operators recognize it without thinking. This clarity reduces reaction time and prevents hesitation.

Conclusion:

An emergency stop push button is a critical safety device designed to halt machinery quickly during hazardous situations. It differs from standard stop buttons in purpose, design, and function. When used correctly, they provide a fast and dependable response that protects people and equipment alike.

For product inquiries, technical support, or pricing information related to emergency stop push buttons and related components, please contact sales@metal-domes.com