When evaluating dome array manufacturers in Ireland, many engineering teams encounter a common problem: there are very few local manufacturers truly specializing in dome arrays. Most companies tend to focus on EMS, HMI, or system integration. This shifts the focus of selecting the top 10 dome array manufacturers in Ireland from “geographical location” to “engineering capabilities, stable mass production, and delivery certainty.”

Are you facing the following problems?

- Samples can be made, but cannot be reliably replicated in mass production: The initial samples have acceptable tactile feel, but mass production batches show significant deviations in rebound force, affecting the consistency of the final product.

- Customization requirements are simplified or even rejected: Mixed trigger forces, irregularly shaped dome layouts, and special conductive film matching are often met with requests to “switch to a standard solution.”

- Low efficiency in engineering communication: Slow feedback on issues, lack of understanding of dome structure and application scenarios, leading to passive project progress.

- Lack of transparency in delivery times: Sampling and mass production share the same production line, leading to conflicts between rush orders and scheduling, resulting in repeated adjustments to delivery times.

- Unfriendly for automated assembly: Traditional bulk dome solutions increase the difficulty and labor costs of SMT assembly.

End-to-End Process Guarantee from Requirements to Delivery

A truly mature dome array project is not just “order-production-delivery,” but rather controlling risks from the very beginning of requirements definition.

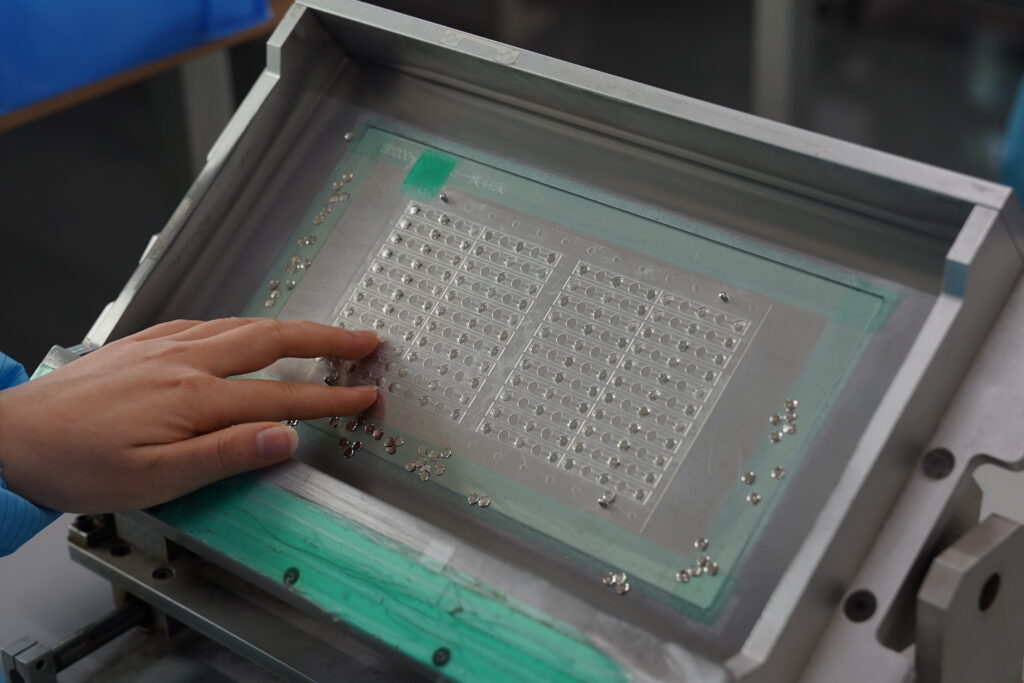

We intervene in application scenario analysis at the early stages of the project, clarifying trigger force, lifespan, key density, and assembly method; completing the matching verification of the dome with the conductive film and PCB structure during the design phase; using the same materials and processes as mass production during the sample stage to ensure reproducibility; and reducing client assembly difficulty through standardized packaging and assembly solutions during the delivery phase.

This engineering-driven + process standardization model is precisely why many Irish customers choose EBest Circuit (Best Technology) after comparing local suppliers.

Why choose us? EBest Circuit (Best Technology)’s Core Advantages

- Focus on dome arrays: Our core business is metal domes and dome arrays, not ancillary product lines.

- Engineering capabilities exceed sales promises: Every project is evaluated for feasibility by our engineering team, avoiding problems with mass production later on.

- High-consistency mass production capabilities: Through standardized materials and processes, we ensure consistent tactile feel between samples and mass production.

- Support for Tape & Reel automated assembly: Directly compatible with SMT production lines, significantly reducing customer assembly costs. Fast response time and high level of cooperation: suitable for the R&D-driven, fast-paced project requirements of the Irish market.

Top 10 dome array manufacturers in Ireland

| Company Name | Process Capability | Advantage Description |

|---|---|---|

| EBest Circuit (Best Technology) | Metal Dome / Dome Array / Tape & Reel / SMT Adaptation | Focus on dome array, engineering-driven, high consistency |

| Keytec Ireland | HMI / Input Interface | Local interface design experience |

| Pilot Photonics | Precision Electronics Manufacturing | High-end manufacturing capability |

| Eolane Ireland | EMS / PCB Assembly | System-level integration |

| Sanmina Ireland | Large-scale Electronics Assembly | Automated production lines |

| Jabil Ireland | EMS Services | Scalable manufacturing |

| Irish Manufacturing Services | Electronics Assembly | Small-batch support |

| Advant Medical | Medical Electronics | Compliant manufacturing experience |

| Integrated Micro-Electronics | PCB + Assembly | Engineering resources |

| Local HMI Supplier | Panel Assembly | Local support |

How to Choose an Ireland Dome Array Manufacturer?

When choosing a dome array manufacturer in the Irish market, the core issue isn’t “who can take the order,” but rather who can reliably translate the design into a mass-producible product. Truly effective evaluation criteria include:

- Does the manufacturer possess “parameter-level” customization capabilities, rather than just specification selection?

Many suppliers’ so-called customization is limited to selecting existing dome sizes and pressure ratings. EBest Circuit (Best Technology) clearly defines the target trigger force curve at the beginning of the project, achieving targeted control of pressure-stroke characteristics by adjusting dome material thickness, forming height, and rebound structure, rather than simply applying existing specifications.

- Is mass production feasibility verified during the design phase?

Many problems stem not from insufficient production capacity, but from neglecting process limitations during the design phase. EBest Circuit (Best Technology) considers stamping tolerances, bonding accuracy, and subsequent SMT assembly conditions during the design evaluation phase, ensuring the design itself is “suitable for mass production.”

- Does the manufacturer have the ability to control consistency between samples and mass production?

Samples are easy to make, but stable mass production is difficult. EBest Circuit (Best Technology)’s samples are not experimental prototypes, but use the same materials, molds, and equipment parameters as mass production, ensuring that the feel and lifespan curves are reproducible.

- Does the manufacturer understand the customer’s assembly method, rather than just delivering parts?

Simply delivering dome arrays often leaves the problems to the customer. EBest Circuit (Best Technology) provides Tape & Reel Metal Dome solutions directly, depending on whether the customer uses SMT, solving assembly efficiency problems from the manufacturing end.

This is why, after comparing with local Irish suppliers, EBest Circuit (Best Technology) is more like an “engineering partner” than a simple parts supplier.

Core Pain Points of Ireland Dome Array Manufacturers

Based on actual project experience, Irish customers often encounter not a single problem in dome array projects, but a series of chain reactions caused by insufficient engineering capabilities:

- Low success rate of customization, requiring repeated structural modifications

The fundamental reason is the lack of a standardized dome design model. EBest Circuit (Best Technology), through its long-term accumulated dome parameter system, completes the prediction of trigger force and lifespan before prototyping, reducing the passive situation of “doing and then modifying.”

- Batch-to-batch feel fluctuations, resulting in unstable end-user experience

This often stems from inconsistent materials and forming conditions. EBest Circuit (Best Technology) locks down key materials and forming parameters and conducts random inspections and curve comparisons during the bonding stage to ensure that batch-to-batch differences are controllable.

- Low yield rate for complex dome arrangements

Dense key layouts or mixed trigger force arrangements are prone to failure. EBest Circuit (Best Technology) conducts array stability assessments during the dome array design phase to prevent failure issues caused by localized stress concentrations.

- Low assembly efficiency and high labor costs

Traditional bulk packaging solutions are not compatible with automation. EBest Circuit (Best Technology), through its Tape & Reel solution, integrates dome arrays directly into the SMT process, addressing assembly bottlenecks at the source.

How to analyze the production capacity of an Ireland dome array manufacturer?

Evaluating production capacity shouldn’t just focus on “whether they have equipment,” but rather on whether they possess the systemic capability for long-term stable output:

- Do they have a stable metal dome forming process window?

- Can they consistently control rebound force and lifespan curves?

- Can they support multiple specifications in parallel without interference?

- Do they have complete bonding and testing processes?

- Can they maintain consistency as production volume changes?

EBest Circuit (Best Technology)‘s production capacity is demonstrated by:

We don’t rely on single experience or a specific expert, but rather on standardized molds, materials, and process parameters to form a replicable production system. This ensures that whether it’s samples, small batches, or continuous mass production, the same performance benchmark is maintained.

How to evaluate the delivery time of an Ireland dome array manufacturer?

Whether delivery time is reliable depends on whether the process is designed for speed, not just temporary time compression:

- Are sampling and mass production processes separated?

- Do they stock common dome specifications?

- Do they have a fixed sampling schedule, rather than ad-hoc scheduling?

- Do they have standardized packaging methods?

- Are they familiar with the logistics rhythms of international customers?

EBest Circuit (Best Technology) can achieve 2-3 day sample delivery because: We have highly standardized our sampling process and maintain long-term stock of high-frequency dome specifications, combined with a mature Tape & Reel packaging solution, creating an efficient closed loop for production, testing, and delivery.

Ireland Dome Array Manufacturer FAQs

- Q1: Why is it difficult to find professional dome array manufacturers locally in Ireland?

A: The market is more focused on EMS and system integration; professional dome arrays typically come from established supply chains.

- Q2: Is customizing a dome array very risky?

A: The risk comes from insufficient engineering capabilities, not from the customization itself.

- Q3: Does a successful sample mean mass production will be problem-free?

A: This is only meaningful if the sample and mass production share the same manufacturing process.

- Q4: Is Tape & Reel packaging necessary?

A: It is almost essential for automated assembly projects.

When evaluating the top 10 dome array manufacturers in Ireland, the real key is not whether they are local, but whether they possess engineering expertise and stable mass production capabilities. Among the top 10 dome array manufacturers in Ireland, only those capable of systematically addressing customization, consistency, and delivery issues are worthy of long-term partnership.