When sourcing a best dome array manufacturers in Hong Kong, buyers are most concerned not only with price, but also with design feasibility, prototyping speed, batch consistency, and long-term delivery reliability. This article will systematically outline the selection logic for Hong Kong’s BEST dome array manufacturers, starting from actual manufacturing needs, and explain why BEST Technology can be a more reliable long-term partner.

Are you facing the following problems?

- Long prototyping cycles, repeated design revisions, and project delays

- Insufficient dome array structural feasibility, inconsistent feel and lifespan after mass production

- High local manufacturing costs, but complex communication and slow technical response when outsourcing

- Unwillingness to accept small orders, unstable delivery times for large orders, and high supply risks

- Incomplete engineering documentation and missing compliance documents such as RoHS/REACH

- Numerous customization requirements, but manufacturers lack specialized experience in dome arrays

These problems are not uncommon in Hong Kong dome array projects. The fundamental reason is the lack of professional dome array manufacturers that simultaneously possess design understanding, scalable manufacturing capabilities, and a mature quality control system.

End-to-End Process Guarantee from Requirements to Delivery: BEST Technology’s Solution

As a professional manufacturer specializing in metal domes and dome arrays, BEST Technology is involved in demand assessment from the initial stages of the project, rather than simply “manufacturing according to drawings.”

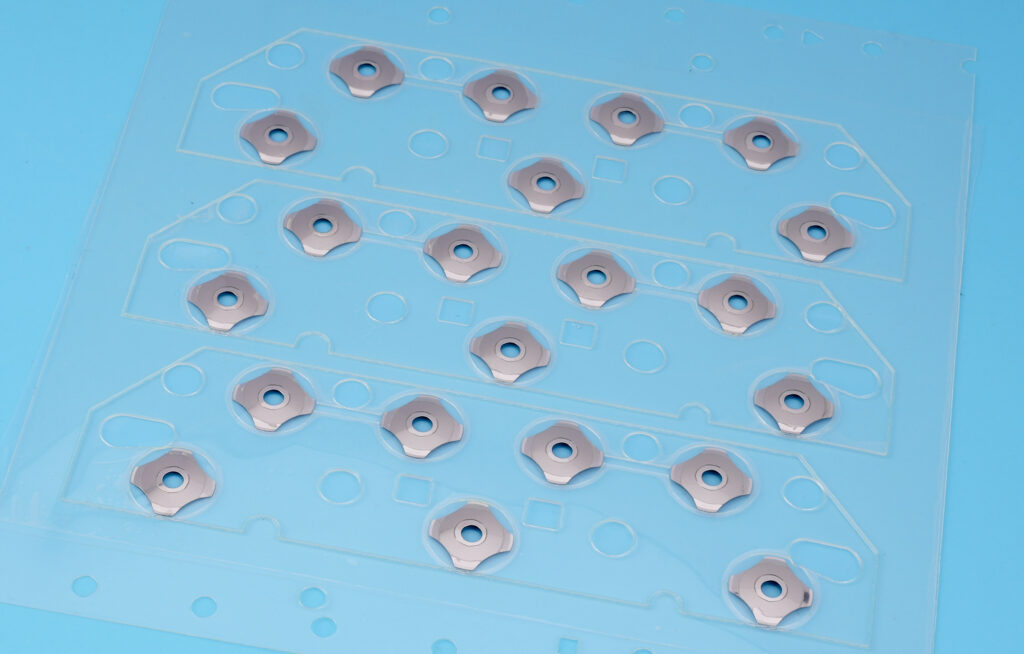

We ensure that every dome array project is controllable in terms of feel, lifespan, assembly efficiency, and delivery time through a complete process of structural feasibility review -> dome selection -> array layout optimization -> sample verification -> mass production -> packaging and delivery.

This risk-reduction model from the source is the core reason why more and more Hong Kong customers choose to cooperate with us long-term.

Why choose us?

20+ years of specialized experience in dome arrays: Focusing on metal domes and dome arrays, not general electronics manufacturing.

- Integrated design to mass production: Optimizing everything from dome force and rebound rate to array layout.

- High consistency and lifespan guarantee: Reliably passing over 1,000,000 press tests.

- Fast prototyping and technical support: Providing complete technical parameters and improvement suggestions during the sampling phase.

- Efficient SMT compatible solutions: Supporting Tape & Reel, significantly improving placement efficiency.

- International compliance and export experience: Fully compliant with RoHS/REACH, serving global customers.

These advantages are not just slogans, but directly translate into shorter project cycles, reduced rework rates, and long-term cost control.

List of Hong Kong dome array manufacturers

Top 10 dome array manufacturers in Hong Kong

| Company Name | Process Capabilities | Core Advantages |

|---|---|---|

| BEST Technology | Dome Design / Array Manufacturing / Tape & Reel | Focus on dome array, integrated design and mass production |

| Johnson Electric | Precision electromechanical components | Strong industrial manufacturing background |

| ASM Pacific Technology | SMT & Packaging equipment | High-end electronics manufacturing capability |

| Wong’s Electronics | EMS / Component manufacturing | Local electronics manufacturing experience |

| Flex Hong Kong | EMS solutions | Global supply chain system |

| VTech Manufacturing | Consumer electronics manufacturing | Large-scale mass production capability |

| New Kinpo Group | EMS | Diversified manufacturing resources |

| GP Industries | Electronic components | Stable industrial customer base |

| Solomon Systech | IC & Modules | Strong technology R&D capability |

| Jetta Company | Precision electronics | Small electronic component manufacturing |

How to choose a Hong Kong dome array manufacturer?

- Do they truly possess specialized dome array experience, or do they rely on temporary outsourcing?

- Can they provide structural and tactile optimization suggestions during the design phase?

- Do they use the same process standards from prototyping to mass production?

- Do they support high-consistency life cycle testing and data traceability?

- Do they offer automated assembly solutions such as Tape & Reel?

- Is their technical response speed fast enough?

- Do they have stable international delivery experience?

BEST Technology possesses systematic capabilities in each of the above areas:

We not only manufacture dome arrays, but also reduce trial-and-error costs, shorten development cycles, and ensure mass production consistency from the design stage. This is the key reason why we are the best choice after comprehensive evaluation.

Core Pain Points of Hong Kong Dome Array Manufacturers

- Disconnection between design and manufacturing: leading to successful samples but failed mass production.

- Insufficient consistency control: significant differences in tactile feel between batches.

- Uncontrollable delivery times: high proportion of outsourcing and unstable supply chain.

- Poor automation compatibility: affecting SMT assembly efficiency.

- High technical communication costs: slow problem feedback.

BEST Technology solves these problems one by one through integrated internal manufacturing, standardized dome array processes, automated packaging solutions, and dedicated technical support mechanisms, ensuring that projects are under control from the very beginning, rather than requiring post-mortem fixes.

How to evaluate the production capacity of a Hong Kong dome array manufacturer?

- Monthly production capacity and expansion flexibility

- Dome molding and array bonding accuracy

- Life cycle and consistency testing capabilities

- Level of automation

- Quality control process

- Raw material stability

- Batch yield data

- Completeness of technical documentation

BEST Technology ensures that dome arrays maintain high consistency and stable yield in mass production through high-precision molds, proprietary process control, full-process QC, and a standardized testing system, rather than relying on manual experience.

How to evaluate the delivery time of a Hong Kong dome array manufacturer?

- Is the sample delivery time fixed and predictable?

- Transparency of mass production scheduling

- Do they have a safety stock mechanism?

- Is the process highly standardized?

- Do they support urgent orders?

- Is packaging and shipping integrated?

BEST Technology significantly shortens the overall delivery cycle through standardized processes + parallel production scheduling + Tape & Reel automated packaging, maintaining fast and stable delivery performance even in customized projects.

Frequently Asked Questions (FAQ) about Hong Kong Dome Array Manufacturers

- Q: Why do samples have a good tactile feel, but mass-produced products are inconsistent?

A: This usually stems from inconsistencies between design and mass production processes, requiring simultaneous control of dome parameters and array layout.

- Q: Is the dome array suitable for automated assembly?

A: Tape & Reel and SMT compatibility need to be considered from the design stage.

- Q: Will small batch production affect quality?

A: Professional manufacturers should use mass production processes even during small batch production.

- Q: How to reduce long-term repair rates?

A: The key lies in lifespan testing and consistency control, not just single-point testing.

- Q: Does customization necessarily extend lead times?

A: When the manufacturing process is standardized and mature, customization does not equal slowness.

If you are evaluating Hong Kong BEST dome array manufacturers and want to achieve a true balance between design, quality, and delivery, choosing a partner with specialized experience and systematic manufacturing capabilities is key to ensuring project success – this is precisely the core value of BEST Technology among Hong Kong BEST dome array ma