Membrane switch assemblies are thin, pressure-activated key interfaces that let users control a device through simple touches. They use layered materials—like a printed overlay and flexible circuit—to register each press with clean and reliable feedback.

What Are Membrane Switches?

Membrane switch is a thin, flexible electrical switch used to turn circuits on and off. It acts as the main interface between a user and a device. When the user presses a specific area on the panel, the pressure causes a circuit to close, which activates a function inside the equipment.

Membrane switch assembly usually includes several layers. These layers come together to create a smooth and durable switching experience. Even though the structure is slim, the design is very powerful. It allows for quick actuation, high reliability, long life, and an attractive front panel.

Furthermore, membrane switches stand out because they keep dust and moisture away from internal circuits.

At Best Technology, our engineers craft membrane switch assemblies for customers who need clean design, precise output, and a long operational life. Each project is tailored so every switch works the way the user expects.

What Do Membrane Switches Look Like?

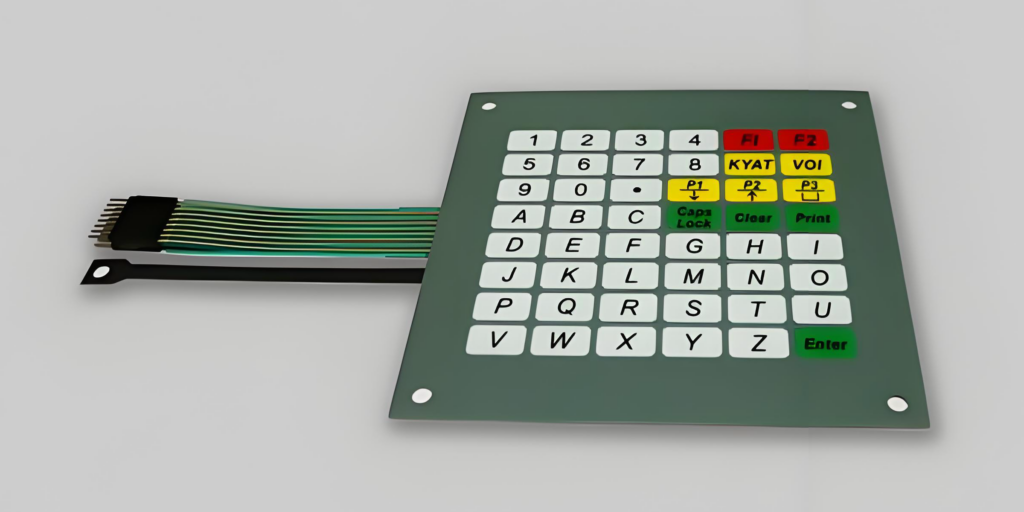

Membrane switches can look completely different depending on the device. They can be sleek, colorful, embossed, flat, or printed with different icons and symbols. They can also be backlit or feature raised buttons for a stronger tactile feel.

Membrane switch assembly looks like a thin graphic interface. It may have printed artwork, labels, windows, or a protective overlay.

Most membrane switch manufacturers, including Best Technology, work closely with designers to match the appearance of the switch with the look and feel of the final device.

Some common visual features include:

- Smooth surface with printed legends

- Embossed key areas for better touch feedback

- Transparent display windows

- LED or light-guide backlights

- UV-resistant top layers

- Glossy, matte, or anti-fingerprint textures

What Are the Different Types of Membrane Switches?

There are several types of membrane switches, and each one serves a different purpose. At Best Technology, we help customers compare options based on their product goals, user experience needs, and environmental conditions.

Here are the main categories:

- 1. Tactile Membrane Switches

Tactile membrane switches create a clear physical “click.” Users feel a small snap when pressing a key. This is usually achieved by adding metal domes beneath the graphic overlay.

Best Technology is one of the leading providers of metal domes and dome arrays, so our tactile membrane switch assemblies deliver sharp and reliable feedback. The dome selection directly affects the user experience, and we help customers choose the ideal dome size and force.

- 2. Non-Tactile Membrane Switches

Non-tactile switches remain completely flat. When pressed, they do not give a physical click. Instead, the device responds electronically or visually. Many consumer electronics, wearables, and sleek dashboards prefer this design because it offers a clean and modern look.

- 3. Metal Dome Membrane Switches

Metal dome switches are the most popular form of tactile membrane switches. A metal dome acts as the main tactile element. When the user presses a key, the dome collapses and closes the circuit. Once the pressure is removed, it returns to its original shape.

Metal dome membrane switches provide:

- Strong tactile feel

- Long life

- High reliability

- Fast response

- Clear actuation feedback

Best Technology manufactures metal domes and metal dome arrays in-house. This allows us to control quality and customize force levels to match the membrane switch design.

4. Flat Flexible Circuits (FFC) and Printed Circuits (FPC)

Some membrane switches use FFC or FPC layers instead of standard printed silver circuits. These versions are stronger and support more complex routing.

They are commonly used in:

- Portable devices

- Compact medical systems

- Industrial instruments

- Smart panels

- 5. Backlit Membrane Switches

Backlit membrane switch assemblies are essential for night-time or low-light operation. Customers can choose LED backlighting, fiber-optic lighting, or light-guide panels.

Backlit switches increase visibility, improve user satisfaction, and add a premium feel. Many appliances, automotive dashboards, and medical panels use backlit designs.

- 6. Capacitive Membrane Switches

Capacitive switches sense the user’s touch through a sensor layer. They require almost no pressure. The user only needs to touch the surface.

They are sleek, modern, and very attractive. They resemble smartphone screens but use a simpler structure. Capacitive membrane switches can also be sealed tightly to protect against dust or liquids.

How Do Membrane Switches Work?

Even though a membrane switch assembly looks simple, its working principle is clever. Several thin layers work together to create a controlled electrical response. This structure keeps the device sealed and helps the switch last for hundreds of thousands—or even millions—of actuations.

Here is a simple explanation of how a membrane switch works:

- The user presses a key area on the graphic overlay.

- This pressure transfers downward to the circuit layer.

- The top contact touches the bottom contact inside the switch.

- The circuit closes.

- The device receives the signal and performs a function.

- When the user releases the key, the contacts return to their original open position.

- For tactile designs, the metal dome provides the snap effect. For non-tactile designs, the response is purely electrical.

The simplicity makes membrane switch assemblies extremely reliable. Since there are fewer moving parts, there is less chance of failure. The closed structure keeps dust, water, chemicals, and oils away from the sensitive electronics.

How Are Membrane Switches Made?

The production of a membrane switch assembly involves many detailed steps. Each layer requires careful printing, controlled alignment, and strict inspection.

At Best Technology, our membrane switch production follows ISO9001 quality standards, using professional equipment for printing, laminating, die-cutting, circuit formation, and final assembly.

Here is how the process works in simple terms:

- 1. Graphic Overlay Printing

The graphic overlay is the top layer. It shows the icons, labels, branding, and artwork. It must be durable, attractive, and resistant to daily use.

Overlay materials often include:

- Polyester (PET)

- Polycarbonate (PC)

- PET is preferred for high reliability and long life. PC is used for beautiful visual effects.

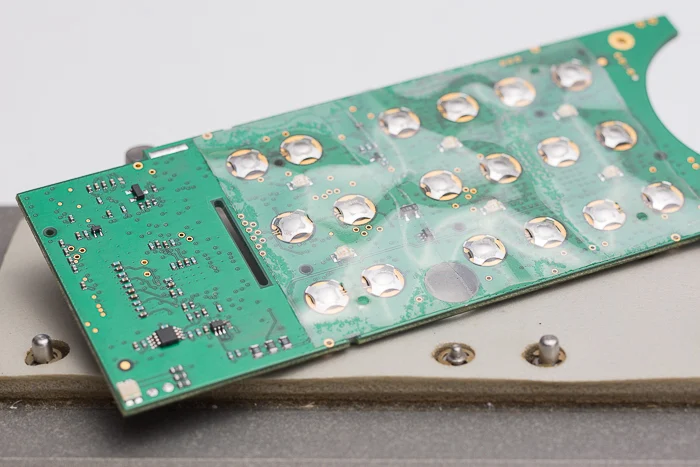

- 2. Circuit Layer Creation

The circuit layer forms the electrical pathways. Its role is to control the flow of signals inside the device.

- Circuit layers can be made using:

- Silver conductive ink printing

- Copper-etched FPC

- Flexible circuits

Best Technology uses high-precision printing to create stable circuit lines for membrane switch assemblies.

- 3. Spacer Layer

A spacer separates the top and bottom contacts. When pressure is applied, the layers meet. When pressure is removed, they separate again.

- 4. Metal Dome Placement (If Tactile)

When a tactile membrane switch assembly is needed, metal domes must be positioned accurately. Best Technology manufactures dome arrays in-house, which gives us excellent control over dome alignment, click force, and long-term stability.

- 5. Adhesive Layering and Lamination

Each layer is laminated using pressure-sensitive adhesives. Proper lamination ensures the switch feels smooth and responds consistently.

- 6. Tail and Connector Formation

The tail is the flexible extension that connects the switch to the device’s main PCB. At Best Technology, we guide customers to choose the right connector type, tail length, and interface.

- 7. Final Assembly and Inspection

After all layers are assembled, the membrane switch undergoes:

- Electrical testing

- Life-cycle testing

- Visual inspections

- Functional checks

Only membrane switch assemblies that pass these checks move to packaging.

This careful process ensures that every switch reaching the customer performs at the highest level.

What Does a Membrane Switch Module Do?

A membrane switch module serves as the control interface for a device. It connects the user’s action to the device’s internal system. It translates a physical press into a digital command.

The purpose of a membrane switch assembly is to:

- Input commands

- Trigger functions

- Display information

- Protect internal electronics

- Improve user experience

- Add aesthetic appeal

- Deliver consistent tactile or non-tactile responses

Most users interact with membrane switches every day. But when designed well, a membrane switch enhances the user’s comfort and confidence.

At Best Technology, we focus on building switch modules that feel responsive, stable, and satisfying to use.

How Long Do Membrane Switches Last?

Membrane switch assemblies can last a long time when made with quality materials. Their lifetime depends on:

- Overlay thickness

- Dome force (for tactile switches)

- Circuit material

- Environmental exposure

- Press frequency

Tactile designs with metal domes usually last longer because the dome shape protects the contacts. Best Technology uses high-performance metal domes with excellent rebound and durability, ensuring a long operating life.

Because the structure is sealed, membrane switches resist:

- Moisture

- Dust

- Oils

- Cleaning chemicals

This makes them ideal for harsh environments where ordinary buttons may wear out quickly.

Where Are Membrane Switch Assemblies Commonly Used?

Membrane switch assemblies appear in almost every industry. Their slim construction, strong sealing, and attractive appearance make them suitable for many environments.

Examples include:

- Patient monitors

- Diagnostic instruments

- Infusion pumps

- Lab analyzers

- Control panels

- Testing machinery

- Automation systems

- Safety equipment

- Home appliances

- Fitness machines

- Smart home panels

- Security devices

- Automotive and Transportation

- Dashboards

- Interior control panels

- Driver consoles

- Commercial and Retail Systems

- POS terminals

- Vending machines

Why Choose Best Technology Co., Ltd. for Membrane Switch Assemblies?

Best Technology is a leading membrane switch manufacturer with more than 18 years of experience. We supply membrane switches, metal domes, dome arrays, and complete interface solutions for customers around the world.

Customers choose us because:

- We deliver consistent quality

- We support OEM and ODM orders

- We design for long life and stable performance

- We provide full customization

- We manufacture dome arrays in-house

- We follow ISO9001 standards

- We offer fast production and responsive support

Our membrane switch assemblies have been used in medical devices, industrial machines, consumer electronics, smart systems, and more. We focus on reliable performance, beautiful appearance, and outstanding value.

Conclusion:

Membrane switch assemblies are powerful, slim, and highly reliable control interfaces. They look simple, yet they support millions of devices in daily life. They can be tactile or non-tactile, flat or embossed, backlit or standard.

If you want dependable membrane switch assemblies for your next project, or if you need help choosing the right design, our team is always here to support you. Contact us: sales@metal-domes.com