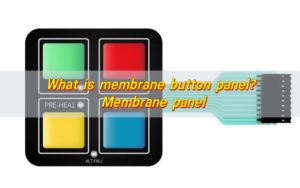

What Is a Membrane Switch Panel?

Membrane switch panel is a low-profile human-machine interface built from flat layers. It looks simple, but each layer plays a key role. The top layer shows the graphics, colors, icons, or symbols. Beneath it is a spacer that keeps the circuits apart. Under that is the circuit layer, which carries the conductive path. When a user presses the top, the layers come together to close the circuit. The device reacts instantly.

This structure stays thin and flexible, yet it can hold up to daily use. Each press feels controlled. When the user pushes the membrane switch button, it completes the action with a smooth and responsive touch.

The modern membrane switch panel is more advanced than older versions. Today, it can include metal dome arrays, LEDs, windows, embossing, waterproof designs, chemical-resistant surfaces, backlight, and strong adhesives. It fits into medical devices, home appliances, security products, tools, and industrial systems.

Membrane switch panels were chosen because they are space-saving, have a clean appearance, and are durable. Even with heavy use, the graphics stay bold and sharp. The surface resists stains, dust, and moisture.

Why Choose a Custom Membrane Switch Panel?

Custom membrane switch panel gives you full control over function, style, and performance. This helps create a device that feels premium and natural to the user.

Custom panels offer impressive flexibility. You can shape the layout, colors, button sizes, tactile feel, travel force, LED feedback, lighting effects, and protection level. You can also choose the exact thickness or material that fits your housing.

Custom solutions support your product identity. A membrane panel switch is often the first point of contact between the user and your device. If it feels satisfying, snappy, bright, and clear, your product feels more advanced.

In many industries, custom membrane switch panels help maintain consistent performance even in harsh conditions. You can choose coatings that resist abrasion, UV exposure, oils, and cleaning chemicals.

Another benefit is improved usability. You can shape buttons with embossing so the user can find them without looking. You can design backlight membrane switch panel features for night use.

Because custom membrane switch panels are thin and compact, they fit well in slim devices.

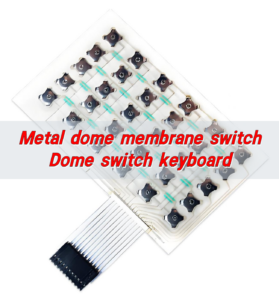

Why Use a Metal Dome Array in Membrane Switch Panels?

Metal dome arrays provide feedback and accuracy to membrane switch panels. When a user presses the button, the dome snaps with a crisp tactile response.

Metal dome arrays also ensure long life. A quality metal dome can last over one million cycles, sometimes even more. This durability makes them ideal for devices used every day, especially in industrial, medical, and communication equipment.

Another benefit is consistency. Every press feels the same. The dome provides stable force, reliable rebound, and uniform actuation.

Metal domes work well with different panel types. They can fit in a membrane switch panels layout or in a metal dome membrane switch that demands more tactile strength.

Metal domes come in many shapes—round, triangle, four-leg, or custom. Each shape changes the touch experience, the travel distance, and the actuation force.

Metal dome array also protects the circuit. It sits between layers and ensures stable contact. This reduces the risk of mis-triggering or weak response.

How Does a Metal Dome Membrane Switch Improve Touch Feel?

Metal dome membrane switch stands out because of its distinctive tactile snap. The dome sits under the graphic layer. When pressed, it collapses with a clear click that tells the user the command was successful.

The tactile feedback comes from the shape, thickness, and force curve of the metal dome. A lighter dome gives a gentle touch. A stronger dome delivers a firm click. This allows full personalization of the user experience.

The metal dome membrane switch also offers a stable rebound. After each press, the dome springs back to its original shape. This quick recovery helps the button stay responsive, even under heavy use.

Another improvement is accuracy. The dome helps guide the press toward the center. When the user pushes the membrane switch button, the feel is always sharp, balanced, and reliable.

Surface design also matters. If the overlay includes embossed buttons, the user can feel the shape before pressing. This helps with tasks where precision matters.

Metal dome switches create a crisp and strong experience without needing mechanical keys. They keep the panel thin but still deliver tactile strength. This is why they are used in professional tools, medical equipment, and high-end consumer devices.

When combined with LEDs or backlight membrane switch panel features, the user gets both tactile and visual confirmation.

What Affects Membrane Switch Button Performance?

Many factors influence how a membrane switch button performs. Each factor shapes the feel, speed, durability, and responsiveness.

- The first factor is material choice. The top overlay must match the environment. Polyester is often chosen because it maintains stable performance even after long use. Polycarbonate is also common, especially in consumer devices. Each material affects flexibility and wear resistance.

- The second factor is circuit design. A clean and well-designed circuit path reduces noise and ensures stable actuation. Silver ink, copper flex, or PET circuits support different types of performance. Their thickness and routing can shape the signal quality.

- The third factor is the spacer layer. This layer controls how much the layers move when pressed. If the spacer is too thick, the press may feel shallow. If it is too thin, the button may not rebound well. An optimized spacer gives a smooth and stable touch.

- The fourth factor is the metal dome or conductive shorting pad. The tactile element defines the actuation force, click ratio, and durability. Each dome size or type offers a unique feel.

- The fifth factor involves adhesives. The adhesive layer bonds the panel to the housing. If the adhesive is strong and stable, the panel stays flat and secure. Poor bonding can create bubbles or lift, which may weaken the button performance.

- Lighting features also influence the performance. LEDs and backlights add visibility. But they must be placed correctly to avoid shadows or uneven brightness. When done right, the lighting enhances the user experience without affecting the tactile function.

- Environmental conditions also matter. Temperature, moisture, oils, and chemicals can affect the surface material. That is why membrane switch panels must use the correct protective coatings.

- Embossing style affects finger guidance. Pillow emboss, rim emboss, and dome emboss each give a different touch.

Clean design also supports better performance. Clear layout, easy-to-read icons, and consistent spacing help users operate the device without confusion.

Where Is a Metal Dome Keyboard Used?

Metal dome keyboard appears in many products that demand accuracy and durability. It is not a typical typing keyboard. Instead, it is a compact interface used in equipment that requires clear tactile feedback.

- You can find metal dome keyboards in professional electronics, such as communication devices, control panels, medical tools, and handheld instruments. They are also used in automotive systems, security devices, and industrial equipment.

- In medical devices, the metal dome keyboard supports cleanable surfaces. The membrane structure stays sealed and easy to disinfect. This helps ensure hygiene without damaging the interface.

- In consumer electronics, the metal dome keyboard brings premium touch feel. Products like remote controls, game controls, or portable gadgets use metal domes to create a strong connection with the user.

- In factories, machines rely on metal dome panels because they withstand intense use.

The consistent response of a metal dome keyboard also reduces errors. It ensures the operator knows exactly when a command has been activated. Because metal dome keyboards are slim, they fit into devices with tight space.

When to Choose a Backlight Membrane Switch Panel?

Backlight membrane switch panel is ideal when your device is used in low-light environments. If your product must work at night, indoors, or in dim places, backlighting becomes essential.

This feature improves the user experience by guiding them through the interface. Bright and clear icons reduce mistakes and increase ease of use. People feel safer and more in control when they can see what they are pressing.

Backlight membrane switch panel is also useful for branding. Soft glow, colored zones, and glowing icons create a premium look.

Many industries rely on this feature. Medical devices need lighting during night shifts. Outdoor controls must remain visible in dark weather. Security systems need clear icons for emergency use. Consumer electronics often add backlight for style and comfort.

Choose backlight when the device must send clear visual feedback, such as status indicators or step guides. With lighting, users can tell if a device is active, charging, locked, or ready to operate.

Backlighting also supports precise tasks. In equipment used for measurements, readings, or adjustments, clear lighting improves accuracy.

Backlight membrane switch panel works well when you want to highlight important keys. Designers can illuminate only certain areas to guide the user toward key functions.

How Does a Backlit Membrane Switch Panel Work?

Backlit membrane switch panel works through a combination of smart structure and precise light sources. It uses LEDs, light guides, EL films, or other lighting elements that sit under or around the button areas.

The process starts with tiny high-efficiency LEDs placed on the circuit layer. Light then passes through a light guide film that spreads it across the panel. The guide ensures even brightness. Small dots or patterns on the film direct the light to the right areas.

The graphic overlay includes translucent windows or printed icons that allow the light to shine through. When the user presses the button, the tactile response remains strong while the light continues to show the action.

Some backlit membrane switch panels use EL film. This creates soft and uniform lighting. It works well for large zones, glowing backgrounds, or soft night glow. LED backlighting, on the other hand, delivers brighter and more focused light.

Backlighting also supports different colors. Red, blue, green, yellow, and white LEDs can be combined to create various effects.

The lighting must be carefully designed so the membrane panel switch stays thin and flexible. Well-integrated lighting technology keeps the structure slim without reducing tactile feel.

Because the lighting sits inside the layers, it stays protected from dust, moisture, and chemicals. This helps the panel last longer.

Conclusion:

Membrane switch panel is more than a simple interface. When paired with a metal dome array, a custom membrane switch panel becomes powerful, precise, and emotionally engaging.

It offers a clean design, excellent durability, a satisfying tactile snap, and endless customization. Features like LEDs, backlighting, embossing, and protective coatings bring extra value.

For project support or detailed customization, reach out to: sales@metal-domes.com