What Is a Capacitive Button?

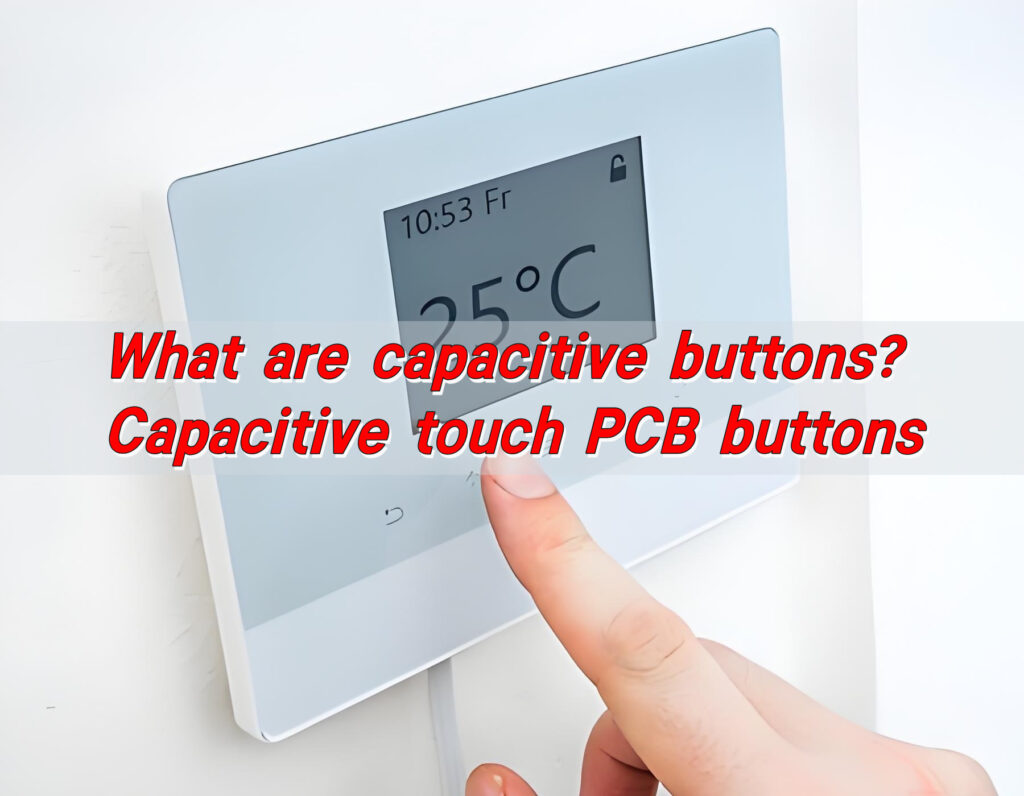

A capacitive button is a type of touch-sensitive switch that detects changes in electrical capacitance when a finger or conductive object nears its surface. Instead of relying on physical pressure like a mechanical button, it reacts to the electrical properties of the human body.

When you touch or approach the surface, your finger changes the local electrostatic field, triggering a signal that registers as a touch.

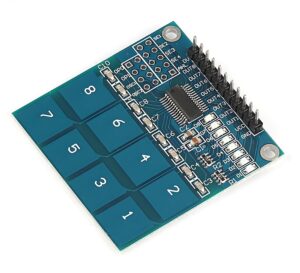

These buttons are commonly integrated into capacitive touch PCB buttons, where the sensing electrodes are etched directly onto the printed circuit board. This design reduces mechanical wear, simplifies manufacturing, and improves reliability.

Capacitive buttons can appear in glass panels, plastic housings, or even under thin metal layers, depending on the product’s design. From smartphones to washing machines, they offer seamless interaction without moving parts.

How Do Capacitive Buttons Work?

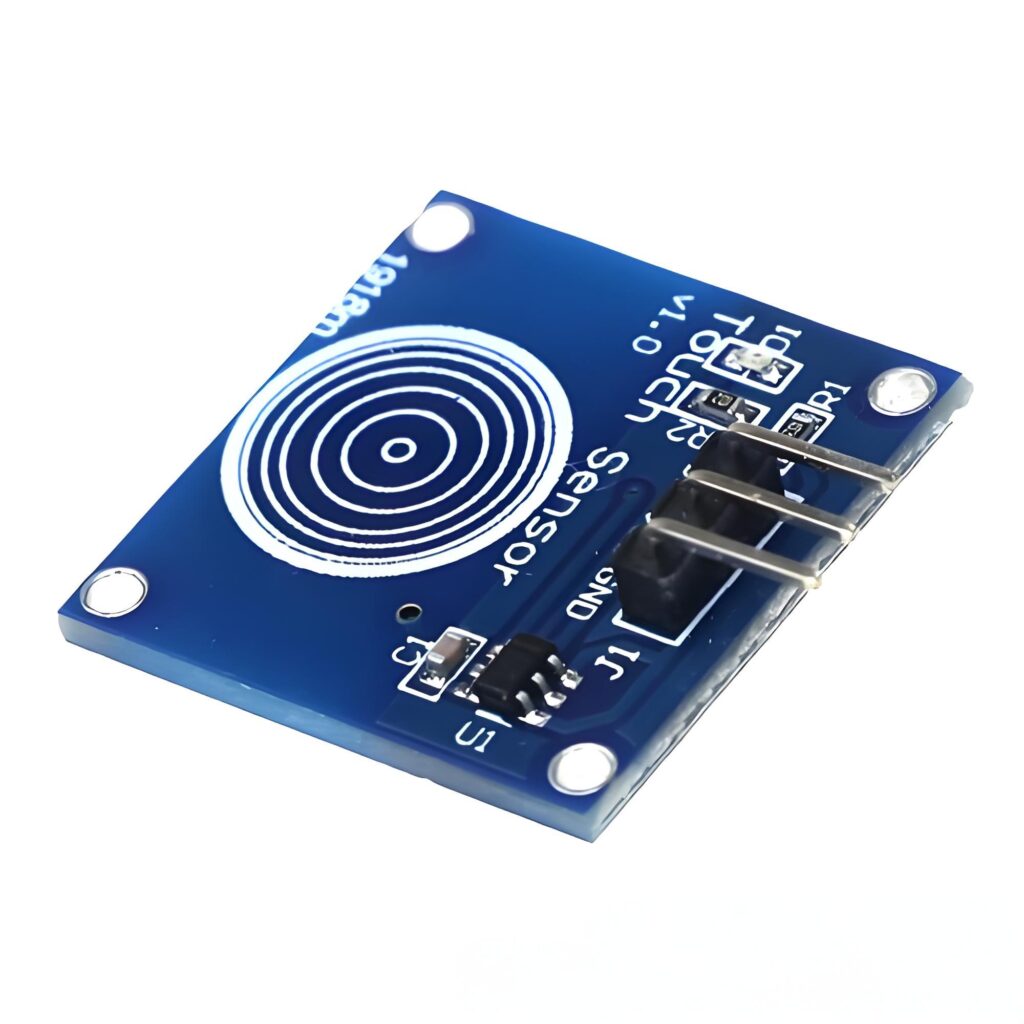

At their core, capacitive buttons are based on a simple principle – capacitance. Capacitance measures the ability of a system to store an electric charge.

Each capacitive button has two conductive layers separated by a non-conductive material (dielectric). When untouched, the system holds a stable capacitance value. When your finger approaches, your body’s natural conductivity alters this value slightly.

Unlike resistive or mechanical buttons that require physical force, capacitive ones depend purely on electrical fields. This allows them to work faster, last longer, and remain unaffected by mechanical fatigue.

Because there’s no need for moving parts, capacitive touch PCBs can be sealed tightly against dust and moisture. This makes them suitable for medical equipment, industrial control panels, and outdoor devices.

Their internal design is also very flexible, allowing sensitivity, debounce settings, and activation thresholds to be adjusted depending on the environment.

How Do Capacitive Touch Buttons Work on Skin Contact or Proximity?

One of the most remarkable traits of capacitive touch buttons is their ability to detect not just direct contact, but also proximity. This happens because the human body carries an electric charge.

When your finger comes close to the sensor, even without touching, it influences the surrounding electric field. The microcontroller measures the difference and decides whether the button is being approached or touched.

This subtle detection capability adds sophistication to user experiences. For instance, some car dashboards light up or activate only when your hand nears the surface. In consumer electronics, this can trigger wake-up functions or illuminate indicators before physical contact.

For skin contact detection, the button’s sensitivity is calibrated to react within a small range — typically within a few millimeters.

In essence, capacitive buttons respond to the “presence” of the user, creating an almost magical feeling of connection between person and device.

Can Touch Capacitive Buttons Work with Gloves or Water?

This question often arises in real-world applications, especially in automotive or outdoor environments. The answer depends on the button’s design and the type of glove or moisture present.

Standard capacitive buttons work best with bare skin since they rely on conductivity. However, advanced designs can detect touches through certain gloves or thin layers of water.

In self-capacitance mode, each button measures its own capacitance value. In mutual-capacitance mode, multiple electrodes work together, allowing more precise and stronger detection — even through insulating layers.

Many capacitive touch PCB buttons in modern cars or industrial panels are specially tuned to respond under wet conditions. In other words, today’s capacitive buttons are becoming more resilient, adaptive, and user-friendly.

How to Disable Capacitive Buttons?

Sometimes, devices include an option to disable capacitive buttons, especially in sensitive or maintenance situations.

On mobile devices, you may find settings under “Navigation” or “Display” to disable or adjust button sensitivity. In industrial or automotive systems, firmware can temporarily deactivate the touch function during cleaning or servicing.

Engineers can also integrate hardware-level controls, like grounding the sensing electrodes or lowering the sensitivity threshold to zero. This approach prevents false triggers during high-humidity or cleaning processes. It offers safety, reduces accidental activation, and protects the system during calibration or maintenance.

In short, capacitive buttons can be easily controlled through intelligent design.

What Causes Capacitive Buttons Not Working Over Time?

Though generally long-lasting, capacitive buttons not working properly over time can result from a few manageable factors.

One common cause is contamination. Dust, oil, or moisture can form a thin layer on the surface, altering capacitance readings.

Another reason could be environmental drift — changes in temperature or humidity that slightly affect the dielectric constant of materials.

Aging of materials can also contribute. Over many years, adhesives or plastics may change in conductivity, affecting sensitivity. Using stable materials and careful PCB layout helps maintain consistent performance.

In rare cases, electrical noise from nearby circuits might interfere. Shielding and proper grounding can minimize this.

Overall, capacitive buttons are highly durable. When designed correctly, they can last for millions of activations with minimal degradation .

What Are Capacitive Push Buttons Most Commonly Used For?

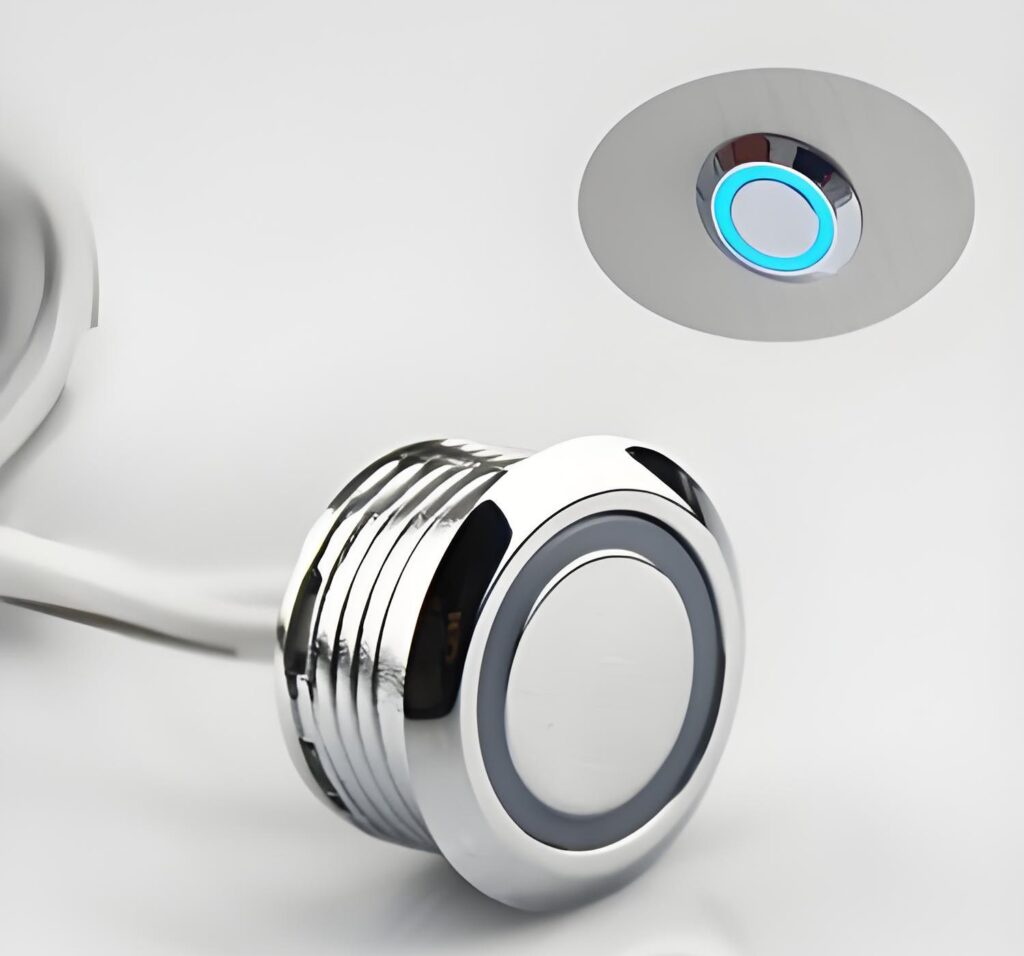

Capacitive push buttons appear almost everywhere today. Their versatility and elegance make them suitable for a wide range of industries.

- In automotive design, they’re increasingly common in dashboards, steering wheels, and infotainment controls.

- In consumer electronics, capacitive buttons dominate in smartphones, tablets, and household appliances.

- Industrial systems use them in control panels where sealed designs prevent dust or fluid ingress.

- In medical equipment, capacitive touch panels are preferred for hygiene.

Their applications continue to expand into elevators, vending machines, lighting systems, and wearable technology.

Why Are Capacitive Buttons Used Instead of Mechanical Switches?

Mechanical switches involve moving parts that wear out over time. They also produce audible clicks, which can be undesirable in quiet environments. In contrast, capacitive buttons have no physical contact points. This means less wear, no sound, and a longer lifespan.

Aesthetic design also plays a major role. Touch-sensitive panels look sleek and futuristic. They integrate easily with glass, metal, or plastic surfaces — perfect for minimalist product designs.

From a manufacturing perspective, capacitive touch PCBs simplify assembly. Fewer components mean fewer points of failure. The result is lower maintenance, higher reliability, and consistent user experience.

Safety and hygiene are additional benefits. Sealed surfaces protect against dirt and moisture, ideal for outdoor or medical devices.

Conclusion:

Capacitive buttons convert human touch into an instant response by detecting changes in capacitance. Well-designed capacitive buttons can operate reliably in wet, cold, or complex environments, with virtually no mechanical wear. They’re not just replacing mechanical switches; they’re redefining the way we design and experience products.

If you’re planning to integrate capacitive buttons into your next design — whether for automotive, industrial, or consumer products — partnering with an experienced PCB manufacturer makes all the difference.

To explore how our PCBs can elevate your touch applications, contact us today at sales@metal-domes.com