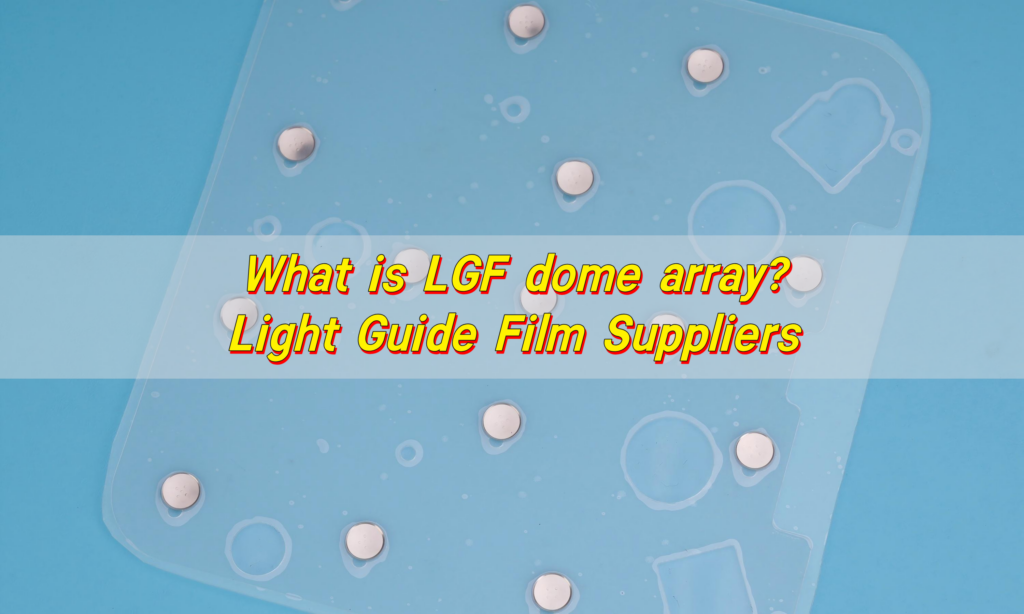

LGF dome array is a new design metal dome array, add a LGF layer on the top of normal dome array. LGF, which full name is Light Guide Film. When we add a LGF on current normal double layer or EMI dome array, it becomes a LGF dome array. It can achieve great result of light distribution.

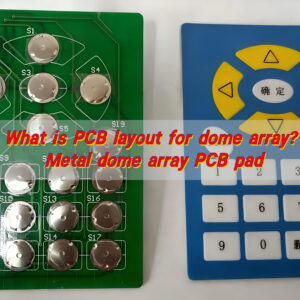

How to design light guide film for dome switches?

Designing an effective light guide film (LGF) requires precision. It’s more than just laying a transparent film over a dome switch.

To begin, you need to know the LED layout on the PCB. In traditional backlighting, about 8–10 LEDs are needed to light up a single keypad area. That consumes power and takes up space.

With LGF dome arrays, we reduce that dramatically—often just 1 to 4 LEDs are enough.

These patterns are not random. They are strategically designed to scatter light evenly across the surface. Some areas may need higher brightness; others, less. So, we create custom densities—either evenly across the surface or more concentrated in select zones.

Designs are also adjusted based on device thickness. The light guide plate film must be thin yet powerful enough to distribute light effectively.

How does an LGF dome array use light guide film?

The LGF dome array integrates light guide film directly onto a traditional dome array, often double-layer or EMI-shielded types.

When LED light enters the LGF layer, it spreads through the film by internal reflection. Thanks to the customized pattern design, this light bounces and exits at specific points—illuminating the area above the domes.

By managing the light path this way, you get excellent light distribution across the keypad. No more dim corners or over-lit zones.

One of the biggest perks is space-saving. Since we need fewer LEDs, the SMT layout becomes simpler, saving you SMT cost, time, and energy.

What is the structure of the LGF dome array?

The structure of LGF dome array contains several essential layers that work together to provide efficient lighting and functionality. These layers include:

- Cover Material: The top layer acts as a protective cover and provides a smooth surface for user interaction.

- Cover Spacer: Located beneath the cover layer, it ensures proper spacing and alignment of internal components.

- Dome Holder: This layer holds the tactile dome firmly in place, ensuring reliable button performance.

- White Spacer: It helps reflect light and distributes it evenly across the surface for better visibility.

- Underlying Circuitry: This functional layer carries the electrical signals to enable the device to operate.

- Adhesive Backing: The final layer that allows the film to adhere securely to different surfaces.

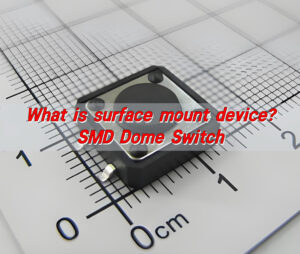

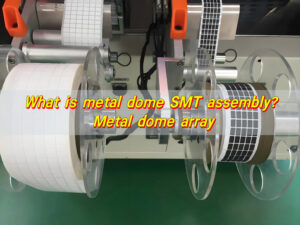

Is SMD dome switch suitable for LGF dome array?

In fact, SMD dome switches are often the preferred choice for LGF integration.

Because they are surface-mounted, SMD domes allow for tighter layout control on the PCB. This gives more room for placing the light guide film and adjusting the LED positioning for optimal performance.

Moreover, SMD dome switches are known for their stable tactile feedback, long life, and small size. These qualities pair well with the LGF dome array, making it a perfect match for slim, high-end devices like mobile phones and smart watches.

So yes, if you want a compact and efficient solution, combining SMD dome switch with LGF is the way to go.

What makes LED light guide film ideal for dome arrays?

LED light guide film makes dome arrays more elegant, more powerful, and more reliable. It can evenly distribute light, remove shadows, and create a luxury visual effect—even under low power conditions.

Here’s why it works so well:

- It uses internal reflection to guide light from a few LED sources.

- The film has a micro-patterned surface, redirecting the light outward.

- It supports custom printing, letting you control brightness, color, and icon design.

- Best of all, it consumes less power, generates less heat, and extends product life.

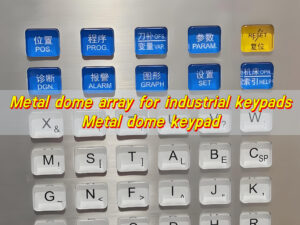

Can a metal dome switch use guiding light film?

Yes. Metal dome switches, known for their crisp tactile feedback, can be transformed into illuminated switch systems by adding a guiding light film. This combination is perfect for industries where performance and appearance both matter.

For example, in medical equipment or automotive consoles, the user interface must be clear and responsive. With LGF added, metal dome switches can offer both—precision touch and bright, even backlighting.

The guiding light film enhances user visibility, especially in dim environments, without compromising dome performance.

How does film lighting guide improve switch visibility?

Visibility is everything in a control panel. Whether it’s a dashboard at night or a wearable on your wrist, users need to see and interact with clarity.

By channeling light from a few LEDs and spreading it evenly, this film removes dark spots, highlights key symbols, and creates a soft glow that’s easy on the eyes.

Unlike traditional light sources that may feel harsh or patchy, the LGF provides a smooth and balanced light field. Plus, we can adjust luminance to match user needs. For instance, our mobile phone LGF dome arrays can reach 30CD/M2 brightness with minimal LEDs.

What are the benefits of LGF dome array in low light?

In low-light environments, the glow of the LGF dome array is clearer.

In situations like nighttime device use, indoor factory operations, or emergency systems, clarity is crucial. Poor lighting leads to errors, fatigue, and poor user experience.

But with an LGF dome array, you get:

- High visibility, even in total darkness.

- Lower energy use, as fewer LEDs are needed.

- Reduced heat output, extending component life.

- Thinner device profiles, perfect for portable electronics.

And because the LGF dome array eliminates the need for multiple LEDs, the product becomes lighter, more compact, and easier to assemble.

In short, it’s the perfect choice for smart lighting in smart devices.

Why choose Best Technology metal dome with LGF?

At Best Technology, we don’t just make dome arrays—we engineer solutions.

Our LGF dome arrays are built to solve your toughest design challenges: uneven brightness, high power use, complex SMT layouts, and limited space. By integrating a custom light guide film, we offer a refined, powerful backlight—requiring fewer LEDs and delivering better results.

Here’s what makes us stand out:

- Precision manufacturing with ±0.05mm contact accuracy.

- Long lifespan, rated at over 1 million cycles.

- Faster delivery, we offer 2-3 day turnaround, compared to the industry’s 7-15.

- Affordable scale, with up to 15% discount on bulk orders.

- Free sampling and full technical support (including ROHS/REACH reports).

- Customized color, shape, and artwork options for LGF dome arrays.

Whether you need dome arrays for phones, automotive panels, wearables, or industrial machines, our team can make it brighter, smarter, and better.

Conclusion:

The LGF dome array incorporates a light guiding film design that provides smooth, uniform lighting with fewer LEDs, lower power consumption and better visibility. From mobile devices to medical tools, this technology enables elegant, user-friendly designs.

Best Technology is your trusted supplier for LGF dome arrays, providing smart solutions for smarter devices.

Ready to upgrade your dome switch lighting? Contact us at sales@metal-domes.com