As a professional metal dome and switch solution suppliers, BEST Technology is committed to providing customers with high-quality metal domes and dome switch products. Our products are widely used in membrane switches, PCB circuit boards, FPC flexible circuit boards and other fields, ensuring that each switch can provide precise tactile feedback and reliable performance.

What is metal dome?

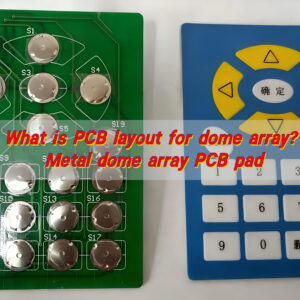

Metal dome is a small, stainless-steel disk used in switch assemblies to provide tactile feedback. When pressed, it collapses and completes a circuit, producing that familiar “snap” feeling. When released, it returns to its original shape, resetting the switch.

This structure isn’t just functional—it’s brilliant. With their dome shape, these tiny parts offer responsiveness, durability, and consistency. You’ll find them in membrane switches, control panels, remote controls, and dozens of compact devices. They’re lightweight, ultra-reliable, and incredibly effective.

Different shapes—round, four-leg, triangle, or oblong—offer various actuation forces. You can customize them to suit different applications, depending on your desired touch feel and circuit layout.

Why choose reliable dome suppliers?

Let’s be honest: not all domes suppliers are equal. Many promise, few deliver.

A reliable supplier guarantees consistent quality, fast lead times, and full customization options. They provide full traceability, advanced quality testing, and an understanding of your application.

Bad domes create costly problems. Poor tolerance, uneven click feeling, or weak life cycles can compromise your entire product.

That’s why partnering with dependable metal dome manufacturers is a must. When the domes are precise, your end users get that premium tactile experience that builds brand trust.

Reliable suppliers offer: Full testing before shipment?Batch tracking and inspection?Custom shapes, forces, and plating options?Support for both prototyping and high-volume production.

How do metal domes work?

The working principle behind a metal dome switch is simple but elegant. It involves three main elements:

The metal dome?Printed circuit board (PCB) or flexible circuit?Spacer or overlay that keeps the dome in place

When a user presses on the overlay, the metal dome deforms and connects two circuit traces below. This action closes the circuit, registering the input. Once the pressure is removed, the dome springs back into shape, reopening the circuit.

No external power is needed. No bulky mechanics. Just pure, efficient design. This simple mechanism allows high-speed responses, making them ideal for industrial, medical, and consumer electronics.

What are metal dome switches used for?

The applications are nearly endless. From medical equipment to military-grade devices, metal dome switches bring precision and reliability.

You’ll find them in:

- Medical keyboards

- Smart meters

- Industrial control panels

- Automotive dashboards

- Consumer electronics

- Remote controls

- Home appliances

These switches are not just about functionality—they also shape the user experience. That firm “click” confirms that a button was pressed. In critical environments like hospitals or factories, that clarity matters.

They’re also ultra-durable. With lifespans up to 1 million clicks or more, they outlast most alternatives. That’s one reason why manufacturers are shifting from rubber or membrane-only solutions to metal dome options.

Why are metal domes better for tactile feedback?

Users want to know their input was received. They want a response they can feel. That’s where metal domes shine. Compared to rubber domes or flat membrane contacts, they provide a crisp, reliable click. They don’t just offer feedback—they offer confidence.

The advantages of metal dome are:

- They’re customizable in actuation force

- They provide a consistent feel across millions of presses

- They work seamlessly in thin, lightweight assemblies

How do metal domes improve switch performance?

Switch performance is more than just function. It’s about speed, reliability, durability, and user satisfaction.

Their snap-action design reduces response time. The mechanical feedback ensures users don’t have to guess whether a button worked. They’re also incredibly resilient. Stainless steel construction resists corrosion, fatigue, and temperature extremes.

By upgrading your switches to include metal domes, you get:

- Faster actuation and reset

- Extended product lifespan

- Lower maintenance needs

- Improved user interaction

They also offer uniform electrical resistance, preventing bounce and ensuring clean signal delivery. Whether you’re building a low-cost consumer device or a critical control system, metal domes raise the bar.

Why BEST Technology is trusted for metal domes?

In the world of dome suppliers, With over 18 years of expertise in electronic components, they’ve become a leader in metal dome manufacturing.

What sets them apart?

- In-house production in China and Vietnam

- Rapid prototyping and small-volume support

- Customization from shape to actuation force

- Precision manufacturing with strict quality control

- On-time delivery and responsive service

Whether you need round domes for a compact PCB or four-leg domes for a rugged application, they can build what you need—fast and to exact spec.

They’ve served industries from medical to military and everything in between. When quality matters, clients choose BEST Technology again and again.

What is BEST Technology’s dome advantage?

BEST Technology’s metal dome products don’t just meet industry standards—they exceed them.

Here’s what gives We an edge:

- Unmatched Quality Control: Every batch goes through rigorous testing—from force analysis to dome symmetry. This ensures every piece performs as expected, right out of the box.

- Full Customization: Our engineers can match your specs precisely. Custom tools and rapid molds speed up development without sacrificing quality.

- Global Support, Local Speed: With factories in Asia and clients worldwide, we balance global reach with local service.

- Stable Supply Chain: Our long-term material partnerships and in-house capabilities reduce delays and risk.

- Continuous Improvement: From better plating processes to cleaner die cuts, our team constantly improves manufacturing for longer life and stronger performance.

When you choose BEST Technology metal domes, you get performance you can trust—and a partner you can count on.

Conclusion:

Best Technology manufactures metal domes, dome arrays and polymer domes, and provides die-cutting services. It also provides a variety of packaging methods, including bulk domes, plastic tube packaging, tape and reel packaging, and dome array packaging.

In addition, we also manufacture poly domes switches made from conductive ink on polyester. Ready to get started? Reach out now at sales@metal-domes.com and experience the BEST in dome technology.