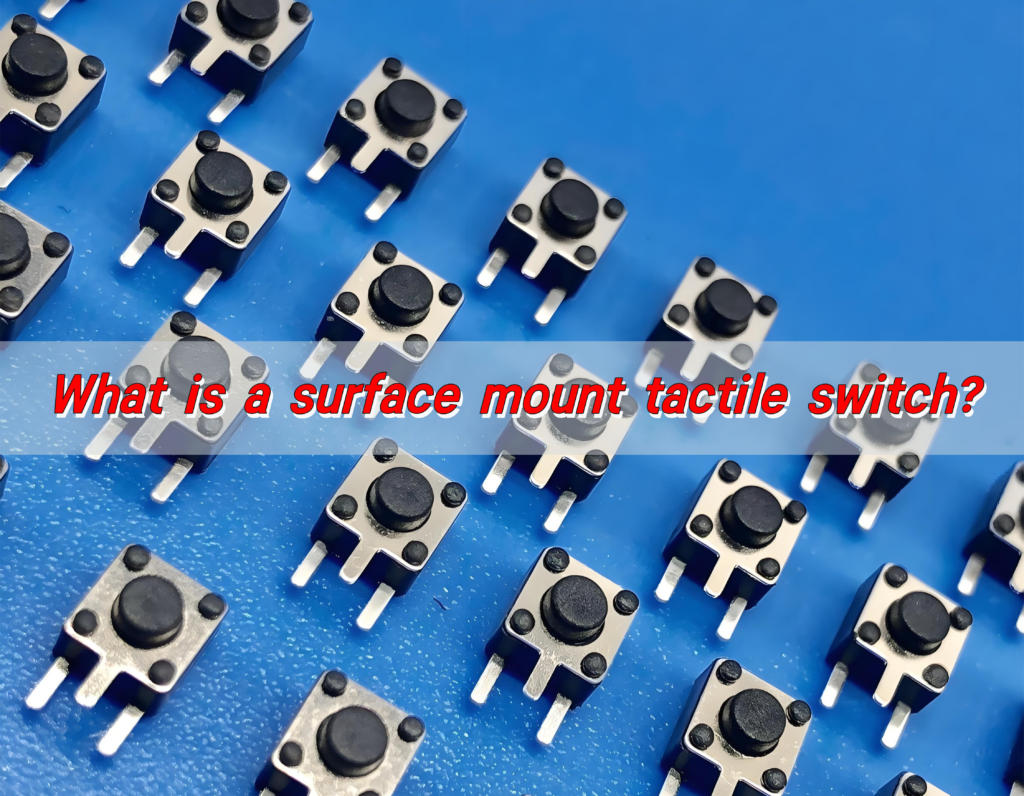

Surface mount tactile switch is a switch that uses surface mount technology (SMT) and is widely used in electronic devices. It switches the circuit on and off by pressing, and has the advantages of miniaturization, high performance, and easy automated production.

Metal dome switch, as one type of switch, uses the elastic deformation of metal dome to provide tactile feedback and is widely used in membrane switches and touch switches.

What is a surface mount tactile switch?

Surface mount tactile switch is a momentary push-button switch. When you press it, the circuit closes, and when you release, it opens. This momentary action gives a responsive “click” feel. It’s known for its low profile and compact footprint, making it ideal for space-sensitive designs.

Unlike traditional through-hole switches, these mount directly on the surface of the circuit board. This design saves space and simplifies automated assembly.

How to solder pcb tactile switch surface mount?

Start with a clean board. Apply solder paste to the PCB pads where the switch will sit. Use a pick-and-place machine or tweezers to position the switch carefully on the board.

Then comes reflow soldering. This process heats the paste until it melts, bonding the switch to the board. Make sure your temperature profile is right—too hot and you risk damaging the switch; too cool and the solder won’t flow.

For delicate jobs or one-offs, hand soldering is also an option. Just use a fine-tip iron and minimal solder. Precision matters here. Too much solder and you’ll create shorts. Too little and the switch won’t hold.

This careful process ensures that your sealed surface mount tactile switch, tactile surface mount switch, or surface mount tactile snap dome switch is secured tightly and ready for years of use.

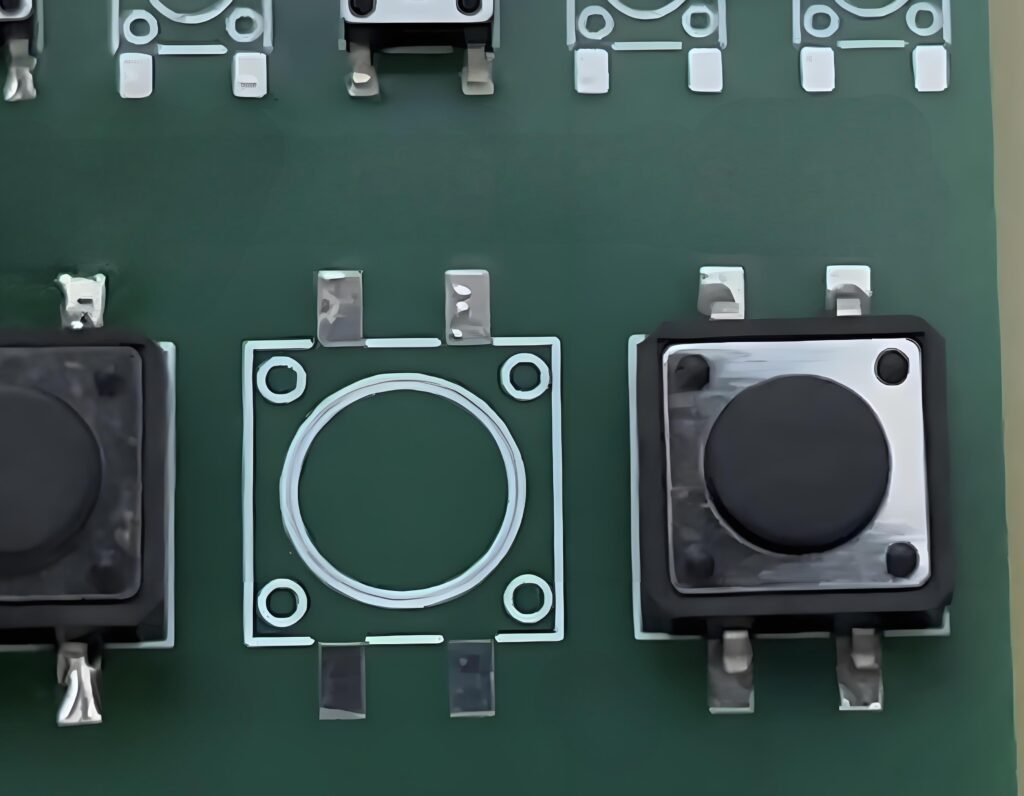

Why use a snap dome in a surface mount switch?

Snap domes are what make tactile switches truly “tactile.” These tiny metal domes sit beneath the actuator and snap when pressed, providing that sharp, responsive feedback.

When you use a surface mount tactile snap dome switch, you’re getting more than a click—you’re getting reliability, responsiveness, and control. These domes also help the switch return to its original position, extending its lifespan.

The crisp tactile feel matters in many applications. Whether it’s a surface mount tactile switch with cap, panel mount tactile button, or panel mount touch switch, the snap dome gives users confidence.

Snap domes also come in different shapes and forces. That means you can customize the feel—from soft and quiet to firm and loud—depending on your application.

What is the advantage of surface mount?

First, size. A small surface mount tactile switch takes up minimal space. That means designers can pack more features into smaller devices.

Second, cost. SMT allows for high-speed automated assembly. More speed equals lower labor costs.

Third, performance. Surface mount connections are short and direct. That improves signal speed and reduces electromagnetic interference. Better signals mean better device performance.

Finally, durability. SMT switches are less prone to physical stress. Once soldered properly, they hold strong—ideal for demanding environments.

Whether it’s a white surface mount tactile switch, tactile switch spst-no top actuated surface mount, or a tactile switch vertical, the advantages are hard to ignore.

What are the disadvantages of surface mount technology?

The biggest downside? Repairs. If a surface mount tactile button fails, replacing it can be tricky. These components are small and tightly packed. It takes skilled hands and the right tools to fix.

Another challenge is mechanical strength. SMT parts are strong in operation, but if they’re pulled or twisted, they can break free.

Also, the initial setup for automated SMT assembly can be costly. If you’re building only a few units, that may not be cost-effective.

Still, the pros far outweigh the cons for most designs—especially when space, speed, and precision matter.

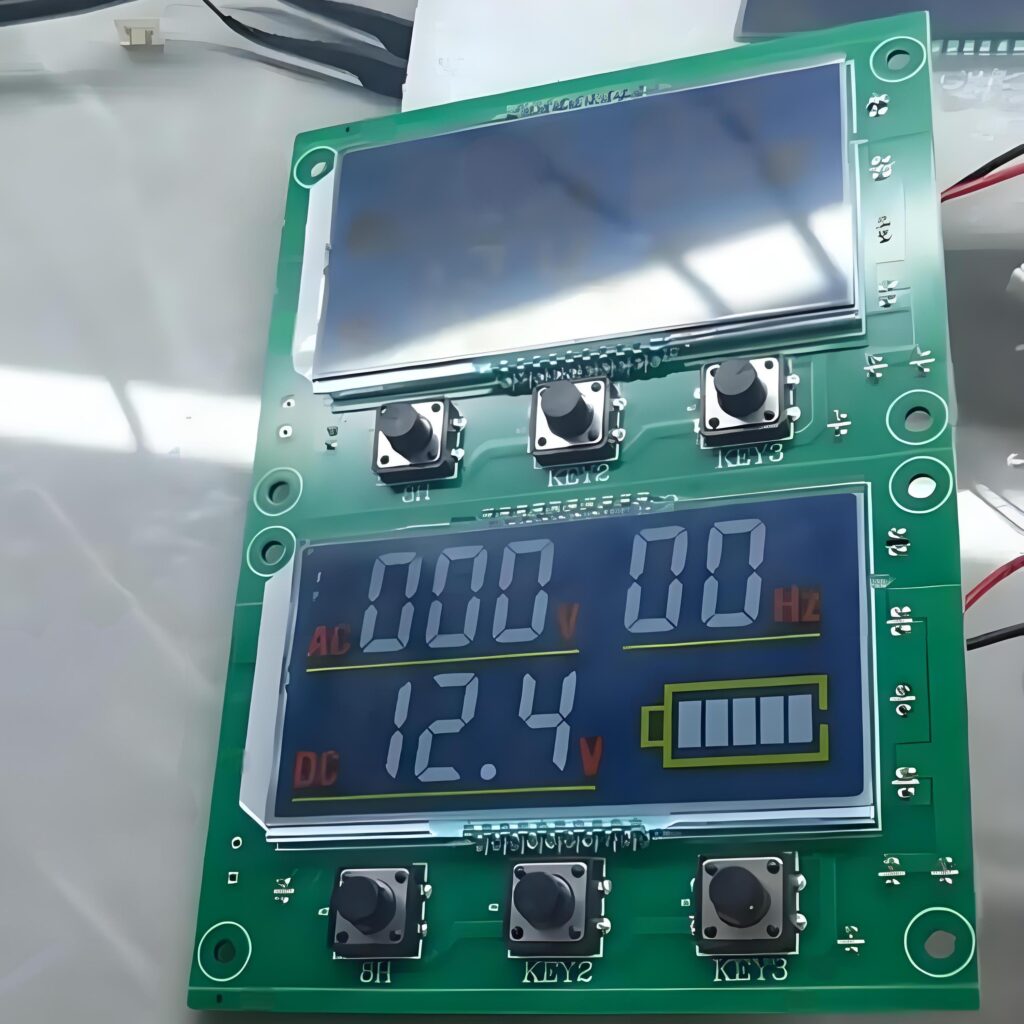

What are surface mount devices used for?

Surface mount tactile switches show up in almost every industry. You’ll find them in consumer electronics, industrial equipment, medical tools, and automotive systems.

Think smartphones, TV remotes, car dashboards, and medical monitors. In all these places, reliable button response is critical.

Because of their small size, they fit perfectly into handheld gadgets. And because they’re easy to assemble in large quantities, they’re ideal for mass production.

Even niche applications like tact tactile push button momentary switch SMD surface mount designs rely on these components for consistent results.

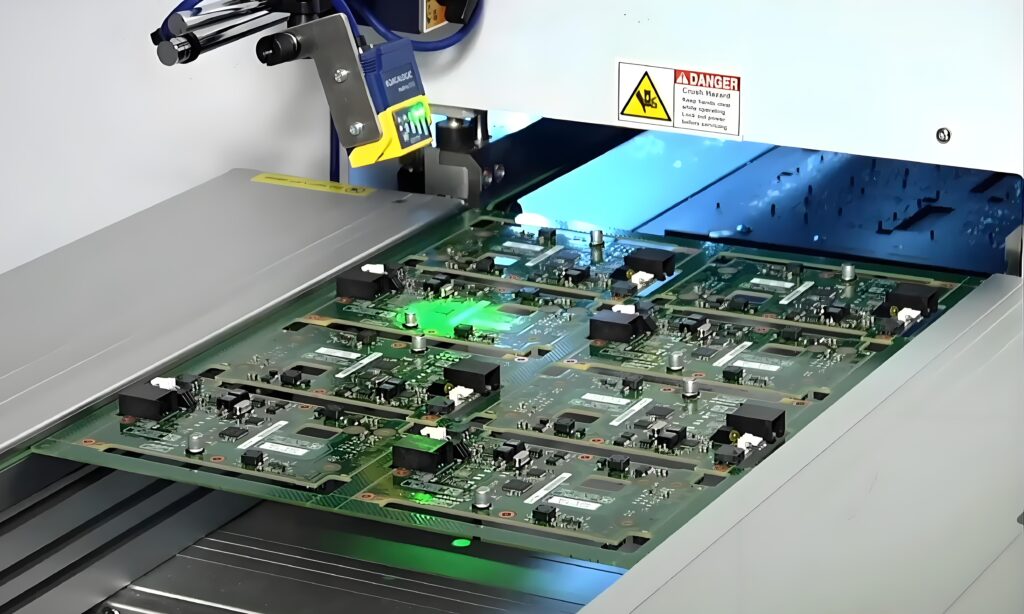

How does surface mounting work?

The SMT process is both technical and efficient. First, a solder paste stencil applies the paste onto PCB pads. Then pick-and-place machines position each component—including surface mount tactile switches—exactly where they belong.

Next comes reflow soldering. This heats the entire board until the solder melts and bonds each part in place. As it cools, the solder hardens, locking the switch in position.

Every step is automated for precision. It’s fast, accurate, and perfect for high-volume production.

This process ensures your tactile push button switch surface-mount is placed exactly right, performs reliably, and withstands time.

Why use surface mount technology?

Surface mount technology helps save space. That’s vital in modern electronics where every millimeter counts.

It also supports automated production. That means fewer errors, faster assembly, and lower costs.

And because SMT parts are smaller, they weigh less. That’s crucial in aerospace, wearable tech, and mobile devices.

Whether you need a sealed surface mount tactile switch or a panel mount tact switch, SMT keeps your products sleek, strong, and scalable.

Where is surface mount technology used?

In consumer devices, it powers buttons, sensors, and processors. In automotive, it handles dashboard controls and safety systems. In healthcare, it makes medical devices lighter and more efficient.

Even rugged environments benefit from SMT. When paired with the right enclosures and sealing, these components can survive water, dust, vibration, and shock.

You’ll see surface mount tactile switches in:

- Remote controls

- Portable tools

- Diagnostic devices

- Game controllers

- Car infotainment systems

- Industrial panels

Conclusion:

Surface mount tactile switch may be small, but its role is massive. It brings user input to life with a simple, satisfying press. It makes products more compact, responsive, and reliable.

By integrating a snap dome, the tactile feel improves dramatically. And with surface mount technology, production becomes faster, more accurate, and cost-efficient.

Need help choosing or customizing your tactile switch solution? We’re here to assist. Contact us today at sales@metal-domes.com