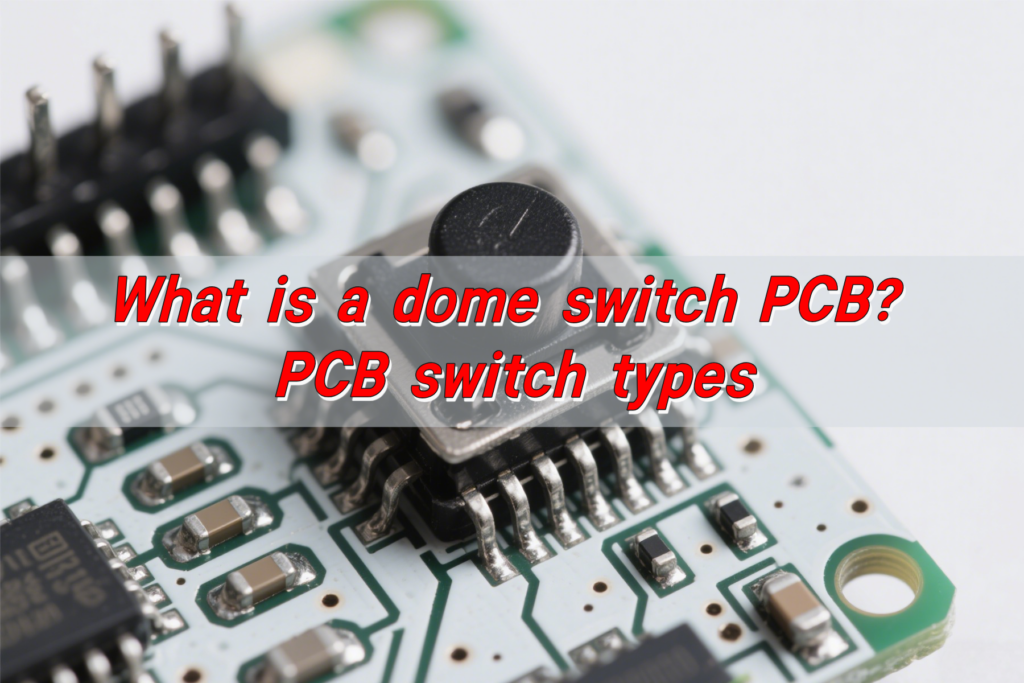

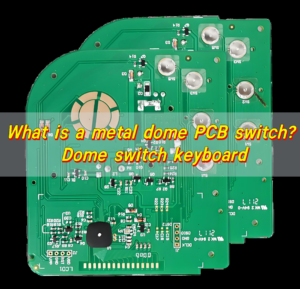

Dome switch PCB is a printed circuit board with metal dome, which is used to control the on and off of the circuit and is widely used in electronic devices. Common PCB switch types include direct plug-in type, surface mount type and touch type switch, which are suitable for different scenarios.

What is a dome switch?

Dome switch is a momentary contact mechanism that relies on a metal dome to complete an electrical circuit. When you press the dome, it collapses, creating contact between two traces on the printed circuit board. Once released, it returns to its original shape, breaking the connection.

This action gives users a crisp, tactile feedback—often described as a “snap.” It reassures them that the button has been successfully activated.

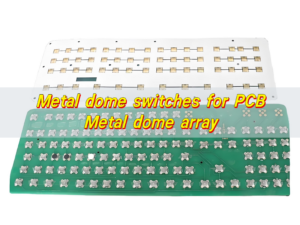

Most dome switches are made of stainless steel. Their shape and strength provide a consistent feel, making them ideal for high-precision environments. These switches are commonly integrated into a PCB (printed circuit board), forming what’s called a dome switch PCB or metal dome PCB switch.

Why use a metal dome PCB membrane switch?

First, the tactile feel is unbeatable. The snap you get when pressing the dome gives instant feedback, reducing the need to press harder or second-guess an input. This improves the user experience tremendously, especially in sensitive equipment or fast-paced environments.

Second, metal domes are durable. These switches can withstand millions of presses without performance loss.

Another advantage is the slim, lightweight design. Unlike bulky mechanical switches, metal dome switch PCBs fit neatly into compact spaces. This allows for sleeker product designs, which is especially important in consumer electronics, wearable tech, and medical tools.

Plus, dome switch PCBs are easy to customize. Whether you need a specific shape, size, force level, or layout, these switches can be tailored to match your exact application.

What are the different types of PCB switches?

The world of PCB switch types is wide. Different switches serve different purposes depending on the design and function of the product.

- Tactile Switches: Known for their short travel and quick feedback. Dome switches fall into this category but offer more tactile clarity than traditional tactile switches.

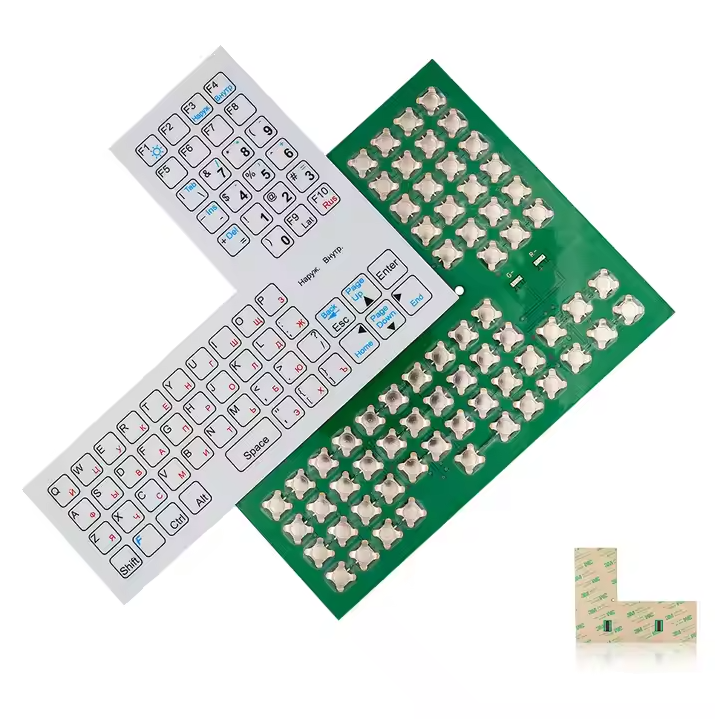

- Membrane Switches: Made of several flexible layers. They often use flat, printed circuits and rely on pressure to create a connection.

- Mechanical Switches: Feature individual components for each key. They offer deeper travel and are common in keyboards but are bulkier and louder.

- Capacitive Switches: Detect changes in capacitance when touched. These are used in touchscreens and sleek interfaces but lack tactile response.

- Dome Button PCBs: A type of metal dome PCB switch that combines tactile feedback with compact design. They’re perfect for applications needing precision and reliability.

Among these, the pcb dome switch stands out for its balance between feel, durability, and design flexibility.

How does a metal dome switch PCB work?

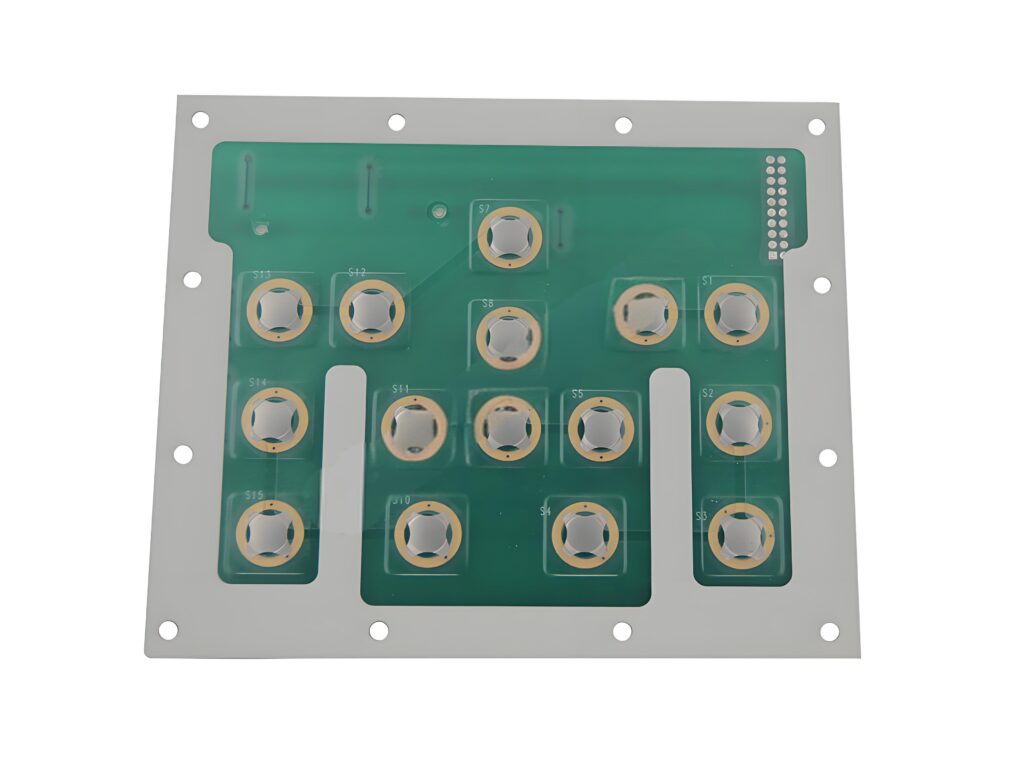

At its core, a metal dome switch PCB is a simple but smart design. The printed circuit board contains conductive traces. Above it sits a metal dome, carefully placed to line up with the contacts on the board.

When the dome is pressed, it collapses inward and touches the traces below, completing the circuit. This action sends an electrical signal to the device, registering a command.

Once pressure is removed, the dome pops back to its original shape, breaking the circuit and ending the command. This “snap-back” motion is what gives the switch its signature tactile feedback.

Fewer moving parts mean fewer things that can break or wear down. And with no exposed parts, these switches can be sealed for protection against dust, moisture, or chemicals.

What makes PCB dome switches reliable?

Reliability is where PCB dome switches shine. They are built to perform consistently—even after millions of cycles.

Made of stainless steel, it resists corrosion, wear, and fatigue. Each dome is engineered to collapse at a specific force and return to shape immediately after release. This ensures every press feels the same, even years later.

Also, because the design is compact and enclosed, there’s less risk of damage from the environment. These switches can be sealed under overlays or integrated into waterproof enclosures, offering enhanced protection for demanding applications.

Their low failure rate and consistent actuation force make them a top choice in critical sectors like medical equipment, aerospace systems, and industrial controls.

How is a dome button PCB different?

While terms like dome switch PCB, metal dome switch PCB, and dome button PCB are often used interchangeably, there are subtle differences.

A dome button PCB specifically refers to a PCB with visible buttons that activate a dome switch beneath. These are often found in devices where the user interacts directly with individual buttons—like handheld remotes or control panels.

In contrast, some metal dome PCB switches might be hidden under a graphic overlay, giving the surface a flat look with marked areas for pressing.

So, the main difference is the user interface. A dome button PCB typically emphasizes individual, clearly defined buttons, while other dome switch designs may focus more on aesthetics or space-saving layouts.

What’s the lifespan of a metal dome PCB switch?

Durability is a major selling point of metal dome PCB switches. Depending on the design and materials, these switches can last from 1 million to over 10 million actuations.

Several factors influence their lifespan:

- Dome material and shape

- Operating force required

- Environmental sealing

- Mounting and overlay quality

In ideal conditions, especially when protected from moisture and contaminants, pcb dome switches can last for years without any drop in performance.

Where are PCB dome switches used?

Here are some key applications:

- Medical Devices: Used in diagnostic tools, monitors, and handheld instruments where quick, accurate input is essential.

- Consumer Electronics: Found in remote controls, wearables, and smart home devices that require compact and reliable switches.

- Automotive: Used in dashboards, steering wheel controls, and interior lighting controls like the car dome light switch.

- Industrial Equipment: Integrated into control panels and machinery interfaces where durability is critical.

- Telecommunications: Essential for devices that must be responsive and long-lasting.

Their adaptability makes metal dome PCB switches one of the most dependable choices across industries.

Conclusion:

Whether you’re building a medical device, automotive controller, or consumer gadget, a metal dome switch PCB brings performance and durability together. Their ability to deliver consistent feedback over millions of cycles ensures a long-term, worry-free experience.

For product inquiries, design support, or custom solutions, feel free to reach out to us at sales@metal-domes.com